Topics: Gas Pipeline

Industrial fans and ventilation are essential for buildings of all types. Compressor station buildings require sophisticated and reliable ventilation for safety, operations, and comfort for personnel. In this article, we will discuss some key purposes of natural gas compressor station ventilation systems as well as some common components in these ventilation systems. Why are Industrial …

Industrial Fans and Ventilation for Compressor Buildings Read More »

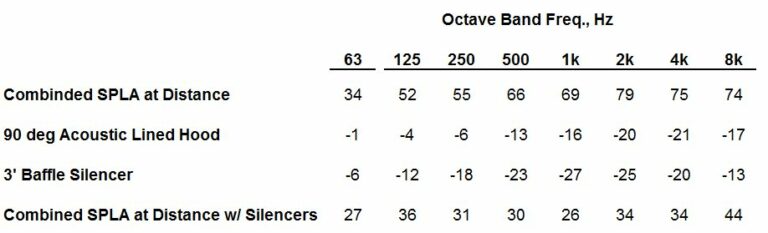

In part 1 of this series, we covered the key terms used in our acoustic calculations. In this second part, we will apply the science of sound to an actual project that I worked on for a gas pipeline customer. Project Requirements Our customer had an overall maximum SPL limit of 50 dBA at 50 …

Meeting Acoustic Requirements Part 2: Acoustic Calculations Read More »

When designing a ventilation system, it is often as important to meet acoustic requirements for the system as it is to meet requirements for air flow and pressure. We see this a lot when we are designing ventilation systems for gas pipeline compressor stations. The specifications for the station will often provide a maximum decibel …

Meeting Acoustic Requirements Part 1: Science of Sound Read More »

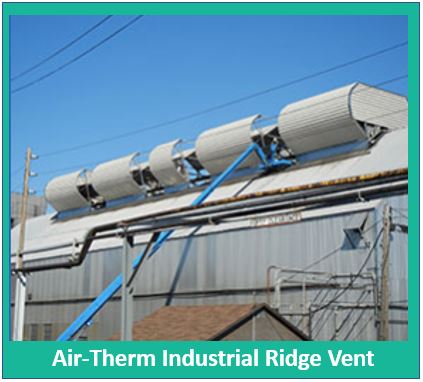

Customers often ask which ventilation system is right for my facility? When Eldridge designs an industrial ventilation system, we do it considering that it needs to accomplish the main goal to exhaust heated or contaminated air from the facility and supply fresh, clean, and ambient temperature outside air. There are four ways that a ventilation …

Which Ventilation System is Right for My Facility? Read More »

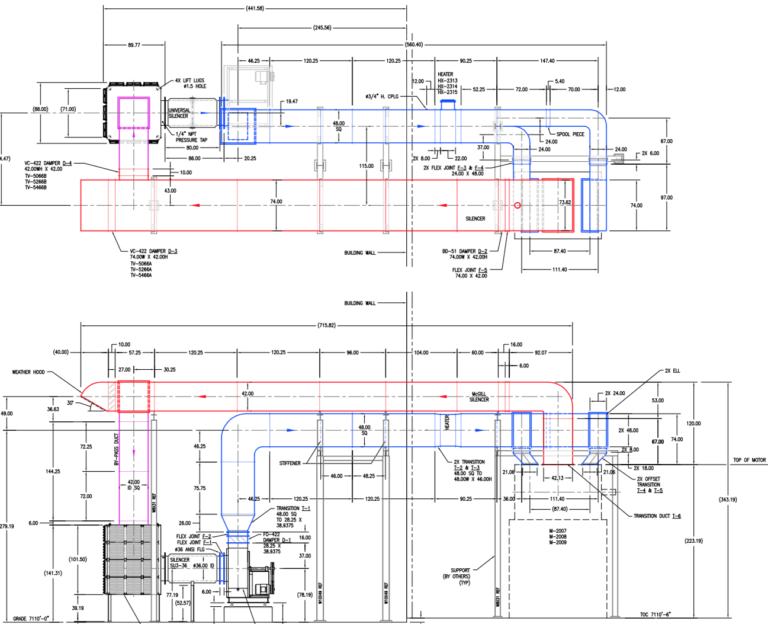

A gas pipeline operator was constructing a new gas compressor station in Southeast Texas. The volume of gas to be moved through the new station would require a 12,500 HP electric motor to turn the compressor. Keeping such a large electric motor cool during operations requires a motor cooling system that can reliably provide a …

Electric Motor Cooling System Design and Manufacturing Read More »

Our first E-Hive Hood was installed around a year ago as part of an Eldridge designed gas pipeline compressor station ventilation system. They were installed as part of a gas pipeline compressor station ventilation system Eldridge designed. Our E-Hive Hoods were a key component in providing adequate air flow for the building while also …

E-Hive Hood Success Story Read More »

Electric motors are becoming the preferred choice for gas pipeline compressor stations. But how do you keep a 20,000 horsepower electric motor cool? We’ll discuss two of the factors that must go into the proper design of an air based motor cooling system to keep these large electric motors running efficiently. Removing Heat Load An …

Electric Motor Cooling System Read More »

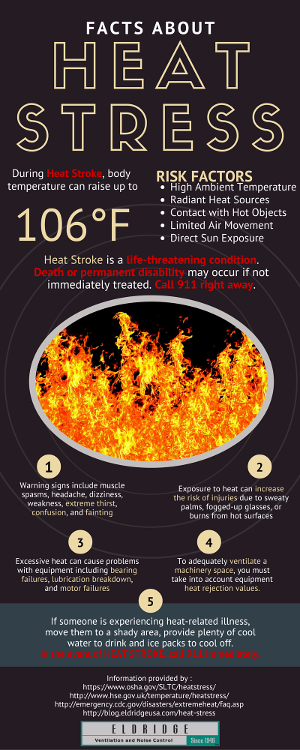

The effects of extreme heat on people, products and equipment in hot weather is a very real concern. Not only can it have a detrimental effect on machinery but of a more major concern, it can be very hazardous and even fatal to people exposed to hot work areas. Luckily, there are precautions you can …

Effects of Extreme Heat Read More »

Gas pipeline compressor building ventilation requires more than just purchasing a couple fans. In our experience, each facility is unique in its own way so there’s not a one-size-fits-all solution for pipeline compressor station ventilation. Taking into account the following 6 factors will bring you closer to a smart solution for compressor station ventilation. 1. …

6 Considerations for Pipeline Compressor Building Ventilation Read More »