The patented Eldridge ENJET product was developed to solve a customer problem with diesel engine exhaust blowing back on to their offshore drilling rig. The customer was ready to go to work, but the US Coast Guard would not certify the rig Eldridge’s ENJET solved their problem by diluting, dispersing, and jetting the engine exhaust away from the rig. Since its first installation in 2005, the Enjet has solved engine exhaust roll back for numerous offshore drilling rig owners and operators.

How It Works

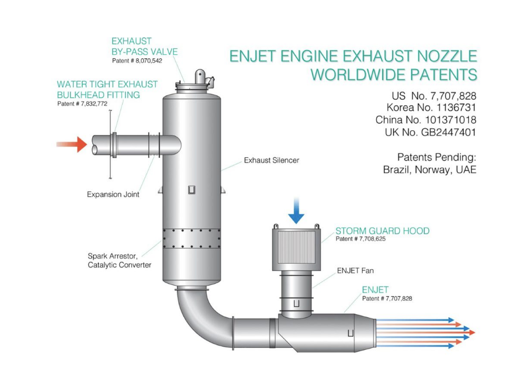

There are several key components that make the ENJET a one of the kind solution for industrial ventilation systems. Primarily used for offshore oil rigs where space is a commodity and moving to avoid exhaust roll back isn’t an option, these industrial exhaust fans offer a unique solution to a dangerous problem.

Using specially designed plenums and air pressurization systems, it sucks in the ambient air and mixes it with engine exhaust gas. The hot and corrosive exhaust gases never come into contact with the air pressurization system’s mechanical components, so you have peace of mind that your system is long-lasting and operates at peak efficiency.

Once exhaust gases are diluted, the ENJET industrial ventilation system shoots the combined mixture through a discharge nozzle at an incredibly high velocity. This high velocity can even overcome high winds and inclement weather conditions to prevent roll back and issues from exhaust fumes, gases, and particulates.

Platform Solution

In recent years, we have also utilized the Eldridge ENJET design for use on fixed or floating production platforms. Although these platforms have the advantage of being able to design the location of engine exhausts by taking advantage of prevailing winds, there are always times when the winds will make engine exhaust a hazard to people working on the decks. In addition to mitigating problems with engine exhaust particulates, the ENJET can be used to dilute and disperse NOx and engine heat away from people and equipment.

Each ENJET application is designed specifically for the wind conditions, platform geometry and engine model/brand. We use our proprietary computer model and algorithm to determine exactly how the ENJET should be set-up to work with and optimize your current system. Let Eldridge help you create a safer environment for people and equipment on your fixed or floating production platform that is trouble by engine exhaust roll back.