CREATING SUCCESSFUL ENVIRONMENTS FOR PEOPLE, PRODUCTS AND PROCESSES

Industrial Ventilation & Noise Control Systems

Industrial Ventilation and Noise Control are essential to any industrial operating environment.

For Workers – their health, safety, comfort, and productivity

For Products – their quality, compliance, integrity, and presentation

For Processes – their efficiency, reliability, and maintainability

More importantly, it speaks to the culture of an organization. That a company values their people, takes pride in their products, and protects their equipment.

As one of many prestigious air ventilation companies, we have been creating successful environments for 75 years. We solve the most complex industrial ventilation and noise control challenges that companies face.

- General ventilation to remove heat load, dictate air change rates, control temperature, humidity, and static pressure within a facility.

- Design and build dust collection, smoke, and fume extraction systems.

- Process fans for moving air and product conveying systems.

- Motor cooling systems, railcar dryers, and sound attenuation for buildings, enclosures, and process equipment.

We are a full-service company that partners with our customers to reach a common objective – solving their ventilation and noise control problems.

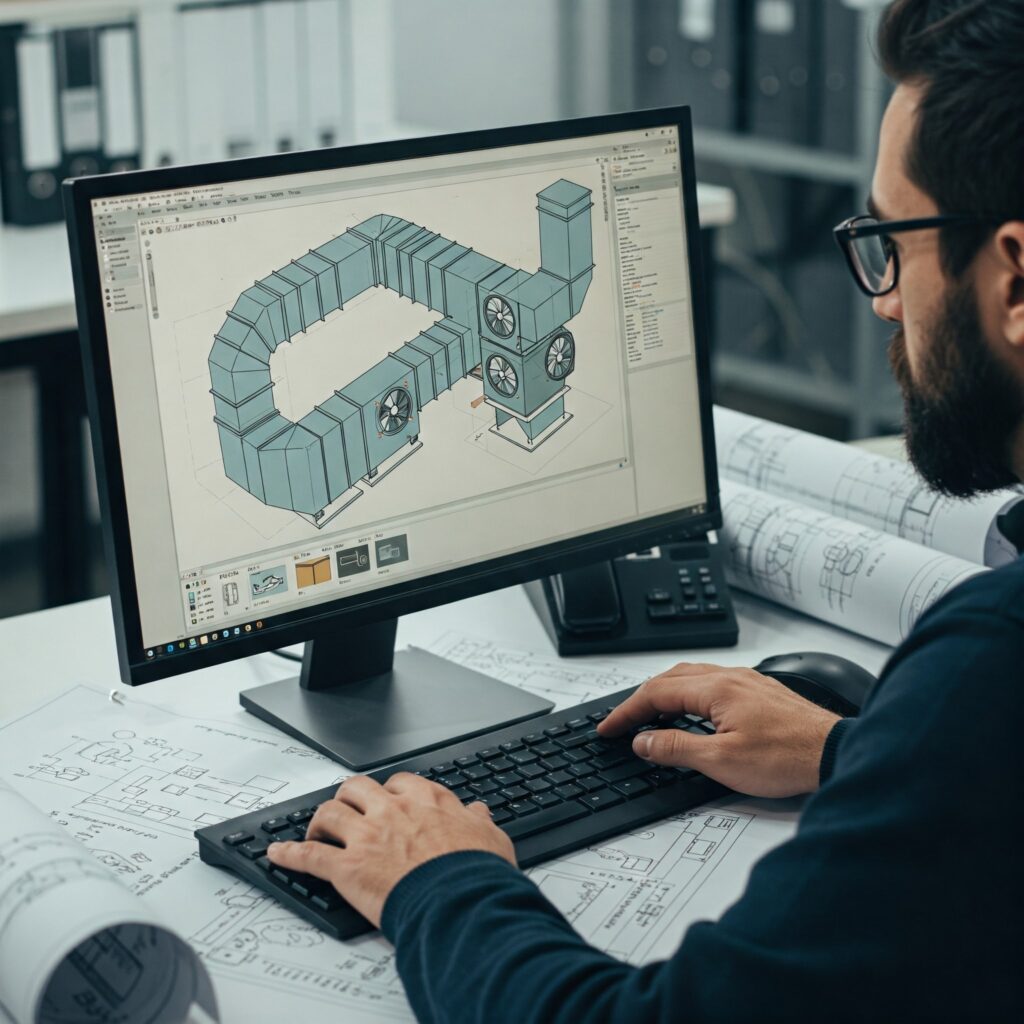

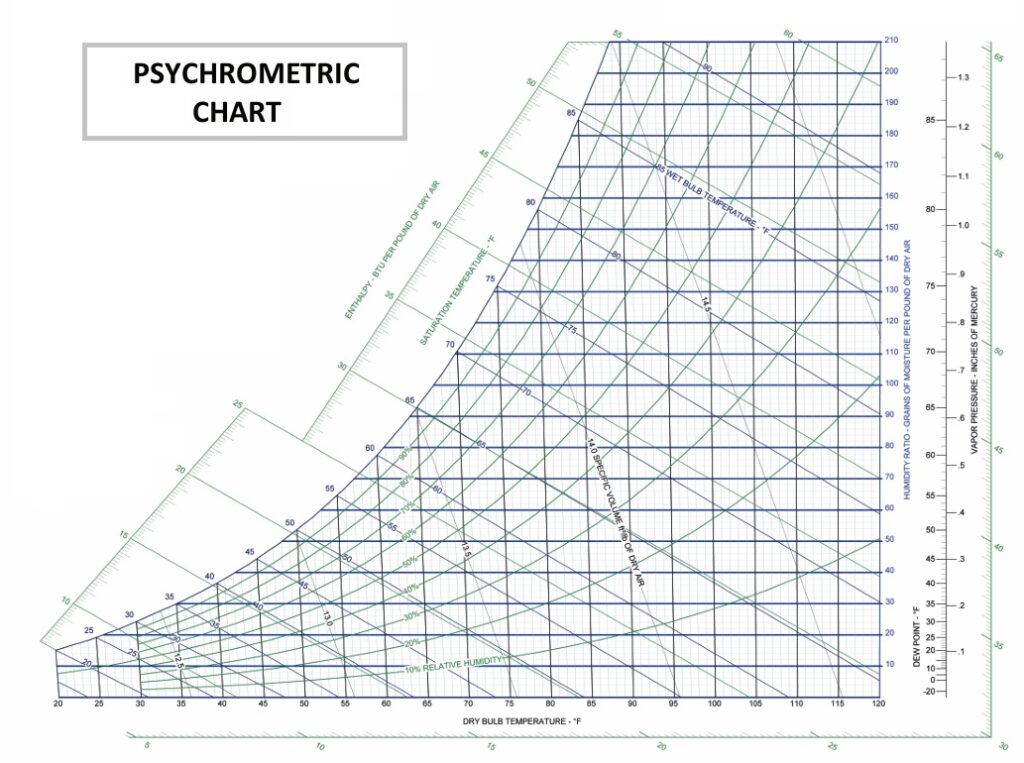

- In house design services providing Heat Load and Psychometric Calculations, Fluid Flow Analysis and CAD

- Supply equipment from industry leading manufacturers of Supply and Exhaust Fans, Process Fans, Spot Cooling Fans, HVLS Fans, Dampers, Louvers, Dehumidifiers, Silencers, Other Sound Attenuating Equipment, Heaters, Evaporative Coolers (Direct and Indirect), Air Purification Systems, Dust Collectors and more…

- Turn-key fabrication and installation through extensive relationships built over 75 years.

Contact us for a free site survey!

Managing Solar and Operational Heat Load / Improving Air Quality

Axial Supply and Exhaust Fans

Proper ventilation can displace 100% of the solar and operational heat load on a building. Eldridge not only guarantees the performance of the fans we provide but also the results that we promise when we are invited to assess your building and all the variables that effect the temperature, air change rates, air quality and static pressure inside of it. Decades of experience in industrial building ventilation has provided Eldridge sales and design teams the knowledge and expertise to ensure we are able to deliver on what we promise.

Meeting Critical Operating Requirements

Process Fans and Dehumidifiers

Products and processes often require specific temperature, humidity, and static pressure conditions to meet quality, safety and/or performance standards. Eldridge has a passion for specifying and providing the right equipment for these critical environments.

- Air Curtains

- Dust Collection

- Extraction Systems

Dealing with Noise

Silencers, Enclosures, and other Noise Abatement Equipment

As you can imagine, most ventilation and process airflow projects have the requirement to meet a noise specification. Eldridge has decades of experience specifying and providing equipment that meets our customer’s noise requirements. Knowing the science of noise and acoustics and how to select the right equipment, is essential to meeting our customer’s expectations and creating a successful environment where noise specifications are involved.

Designing Products to Solve Problems

Ventilation Experts

At Eldridge, we do not limit ourselves to what we have in our catalogs. We often customize solutions to meet the most challenging needs that our customers face. Eldridge holds seven U.S. patents that are the result of solving problems where no solutions existed prior to our involvement. Some of the solutions were essential to protect lives of those working in the area. Engine Exhaust Systems and space efficient Water Removal Hoods for Offshore Drilling Rigs, Explosion Proof Dehumidifiers, and Customized Extraction Systems are a few examples.

- Enjet

- StormGuard Hood

- E-Hive

- Pit Boss

- Design Services

PROVIDING FACTORY COOLING & SOLUTIONS FOR VENTILATION ISSUES IS OUR PASSION

Industrial

Industrial applications require robust and reliable ventilation systems to keep facilities safe and operational. Whether you need general industrial ventilation systems or require more specialized solutions for hazardous duty operations, our ventilation experts are here to design industrial ventilation systems customized to your application.

Marine & MODU

Marine environments require more durable and intrinsically safe ventilation systems. We offer personnel with safety offshore certifications to design, provide and install high-quality, high-performance, and ultra-dependable systems to help control humidity, temperature, and air quality on marine and offshore vessels.

Power Generation

In the power industry reliability is of the utmost importance. For 75 years Eldridge has proven to be a reliable partner to Original Equipment Manufactures and End-Users in the Power Industry. Whether it is a new application or problem solving the ventilation and noise requirements of an existing application, Eldridge can help you create a successful outcome with our full line of ventilation and noise control equipment created specifically for the power industry. Call our experts today to get started.

Gas Pipeline

Gas pipeline compressor stations require high-performance ventilation and noise abatement systems to protect equipment and the surrounding environment. Keeping equipment cool and noise levels safe is essential for long-term operation. Our experts have created countless custom ventilation and noise abatement systems for natural gas compressor stations to keep things running efficiently.

Food Processing

Industrial ventilation systems aren’t just for keeping people cool, they’re also vital for protecting product integrity! In the food processing industry, ventilation systems must meet strict guidelines for climate conditions and air quality. Our ventilation experts design systems to meet and exceed these expectations to help keep your facility operating successfully.

Critical Environment

With a critical environment there are no short cuts. The systems must meet strict filtration requirements but must also be compliant with regards to temperature, humidity, and pressurization. Our experts are here to help you design a system specifically for your critical environment.

Latest News and Resources