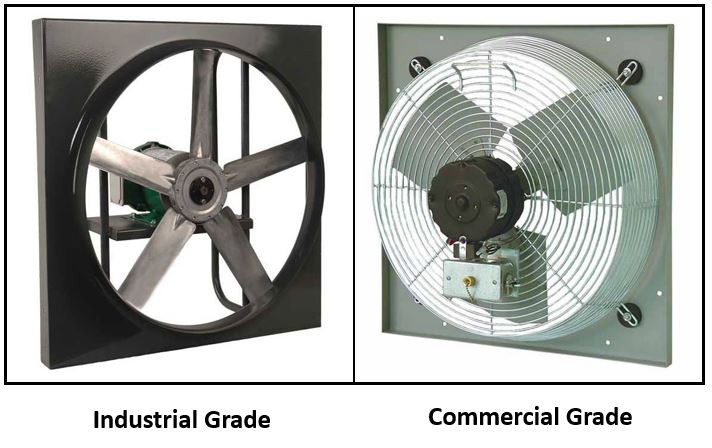

Hot summer weather has many industrial facility owners seeking solutions to provide a more comfortable working environment for their employees. Looking for a quick fix, it may be tempting to buy commercial grade fans from an online supply house. However, putting commercial grade fans in an industrial application will be more expensive in the long run. In this blog, I’ll be comparing industrial and commercial grade fans so that you will understand why industrial grade fans are a better value.

General Characteristics

Here are the general characteristics of industrial and commercial grade fans:

Industrial fans

- Heavy gauge, welded housing construction

- Solid, cast, aerofoil propeller blades

- Heavy duty motors

- Lifecyle is over 10 years

Commercial fans

- Light gauge, bolted housing construction

- Pressed and bolted propeller blades

- Light duty motors

- Lifecyle is 2-4 years

Comparing Differences

Here is a more detailed explanation of the key differences between industrial and commercial grade fans.

Motors

The biggest difference in the lifecycle time of the two grades of fans is the motor. Heat greatly reduces the life of an electric motor. Commercial grade fans use inexpensive motors that aren’t rated for high heat. Because exhaust fans are placed where it is the hottest in a facility, they need to be able to endure a high amount of heat. Over time, the high heat will cause the motor of a commercial grade fan to fail. Industrial fans use heavier duty motors that have high heat ratings and thus, will last significantly longer.

Propeller Blades

The second biggest difference between the two grades of fans is the fan blade construction. Most commercial fans will have pressed metal blades that are riveted to the blade stems. Over time, the flexing of the blade and vibration will cause the metal to crack around the rivet point. That will eventually lead to blade failure and a safety hazard due to flying blade parts. Blades on industrial fans are cast in one piece so there is little risk of failure. Also, the blade shape of an industrial fan is an aerofoil design which means it can move more air with the same or less motor horsepower.

Housings

Durability of the fan housing is also one of the key differences. When a fan motor starts, there is severe stress imposed from the motor on the housing. The heavier gauge material and welded construction of an industrial fan housing makes it better suited to absorb the stress without cracking. Once a fan housing experiences a stress crack, moisture and vibration will eventually lead to failure.

Conclusion

When comparing industrial and commercial grade fans, the differences between the two fan grades are the durability of the motor, propeller blades and housing. While the initial investment is more for an industrial grade fan, over the long run you will end up spending more money to replace the commercial fan two or three times compared to the lifecycle of an industrial fan.

Don’t go the route of a quick fix when your industrial facility needs more ventilation. Call one of our ventilation experts at Eldridge and they will recommend one of our stock Eldridge Fans that best fits your application.