In the second part of this three part series on Dust Collection System Design, we are going to discuss how to determine and maintain transport velocity. After dust particles are captured, the proper transport velocity ensures that the dust particles will be conveyed through the duct work without clogging from the capture point to the dust collector.

Transport Velocity

The second key design criteria for a dust collection system that we want to point out is how to determine and maintain transport velocity throughout all of the ductwork. The standard duct velocity may be appropriate for transporting lighter or drier dust particles through the ductwork all the way to the dust collector. However, heavy or wet dust particles will require a higher transport velocity to prevent settling or plugging.

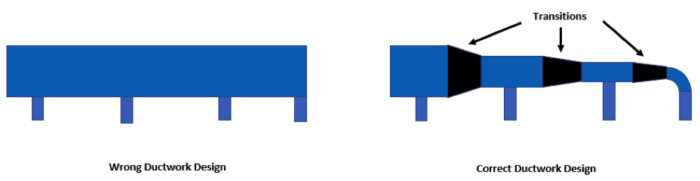

A dust collection system with multiple capture points will need branches in the ductwork for each capture point. Maintaining a consistent transport velocity in these branches and pick-up points is very important. To maintain transport velocity for each collection point downstream of the first one, transitions will need to be used. Otherwise, not all capture points will have sufficient air flow to generate the needed capture velocity.

The sizing of the transition will be determined by how much air flow is required at each collection point. The location of the transitions should be immediately after the duct servicing each collection point.

In the final part of this series, we will discuss the third key design criteria which is total static pressure.