Eldridge is excited to have recently partnered with Cambridge Air Solutions to bring Indirect Evaporative Cooling products to our customers. We believe this technology will be a game changer for cooling indoor environments at significantly lower operating costs. In this three part series on Indirect Evaporative Cooling, I’ll start by first discussing the science that makes it work and the technology that Cambridge incorporated into their products. Then I’ll go through two applications where Indirect Evaporative Cooling will make a significant difference in how indoor environments are cooled.

The Science

The discovery of evaporative cooling dates back to ancient Egypt where people would hang wet blankets in their doorways or have someone else fan them across jugs of water. What the Egyptian’s where utilizing was the air cooling effect that occurs when water changes state from a liquid to a vapor. To make that phase change, the liquid water absorbs heat from the air. When the air gives up the heat, the temperature of the air decreases.

The heat given up by the air during the evaporative cooling process is referred to as sensible heat. The heat required to make the phase change in water from liquid to vapor is referred to as latent heat. In the evaporative cooling process, these two are always equal. The process works best when it starts with hot, dry air, which has the largest amount of sensible heat to give up. The result is air that has become 100% saturated with water vapor, which is air that has absorbed the largest amount of latent heat.

The Technology

The major drawback to using evaporative cooling to cool indoor air is that the humidity in the air will increase significantly. If the indoor space was located in the US Southwest where the relative humidity is low, this would not be a problem. But imagine trying to use it to cool in an indoor place located along the Gulf Coast. The humidity level would go from bad to worse. Even though the temperature would drop some, the higher humidity would increase the heat index or the perceived temperature.

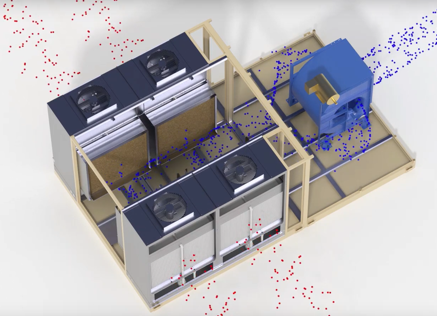

Cambridge incorporated a heat exchanger to separate the wet and dry air streams which eliminates the increase in humidity. The wet air stream is where the evaporative cooling process takes place. The temperature drop that occurs to the wet air stream is transferred to the dry air stream through the conductive walls of the heat exchanger. The cool, dry air stream is what enters the indoor space without having picked up any humidity from the wet air stream.  With this innovate heat exchanger technology, Cambridge Indirect Evaporative Cooling products provide the benefit of cool air without the unwanted increase in humidity. Cambridge has a great video that shows how this innovative technology works in detail:

With this innovate heat exchanger technology, Cambridge Indirect Evaporative Cooling products provide the benefit of cool air without the unwanted increase in humidity. Cambridge has a great video that shows how this innovative technology works in detail:

Parts 2 and 3

In the coming parts of this series, I’ll discuss how Indirect Evaporative Cooling units can be used as an alternative to AC in cooling manufacturing facilities and can work as a pre-cooler when paired with a dedicated outdoor air system (DOAS). Eldridge believes this innovative technology will shake up the cooling market. If you can’t wait to read about the applications, give us a call to have one of our sales ventilation specialists come out and see if this will be a good fit for your facility.