In part 2 of this series, we used acoustic calculations to evaluate whether the combined noise from the interior of a building and a supply fan exceeded a given noise limit. In this third part, we will analyze the use of sound reduction techniques to bring the combined noise in under the noise limit.

Sound Reduction Techniques

Before getting into sound reduction techniques, I need to define another term and that is Dynamic Insertion Loss (DIL). It is the difference in sound levels (dB) at a given location due to placement of a noise control device in the sound path between the sound source while under air flow. That means that the DIL depends on whether the sound is traveling with or against the flow of air. The DIL factors that we will use in the calculations below have been provided by the manufacturers of the noise control products.

For our example project, there are three types of silencing techniques that we will use:

Blocked line of sight: Simply adding a barrier between the sound source and the measurement location will provide some noise reduction. For wall mounted supply and exhaust fans, a 90 degree rollover hood creates a barrier that can provide as much as 3 dB of sound reduction at most frequencies.

Acoustic lining: Placed at the inlet and outlet of sound sources, acoustic lining absorbs the radiated acoustic energy, thereby reducing the far-field noise levels. We use acoustic lining placed on the inside of rollover hoods. The DIL of the acoustic lining depends on the thickness of the lining and the air flow direction.

Inline baffle silencers: The baffles of an inline silencer are designed to convert sound energy to vibration energy. The DIL depends on the silencer length and the type of material used in the baffles.

System Design

As a reminder, here is the SPLA profile, at a distance of 50 feet, for the combined noise that we calculated in part 2:

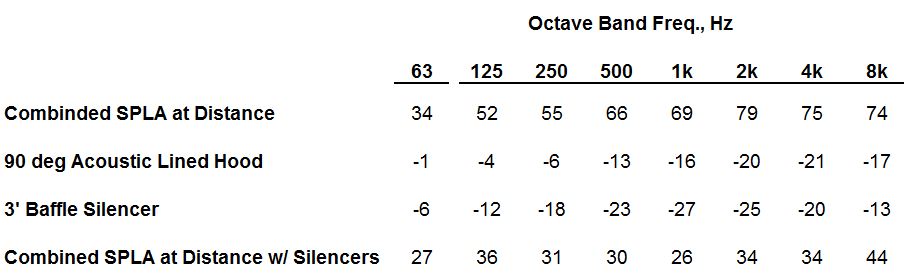

Because our noise problem is in the higher frequencies, we will use all three sound reduction techniques by selecting a 90 degree acoustically lined rollover hood and a 3 foot long baffle silencer. Here is the calculation where we apply the DIL profiles for these two sound reduction devices:

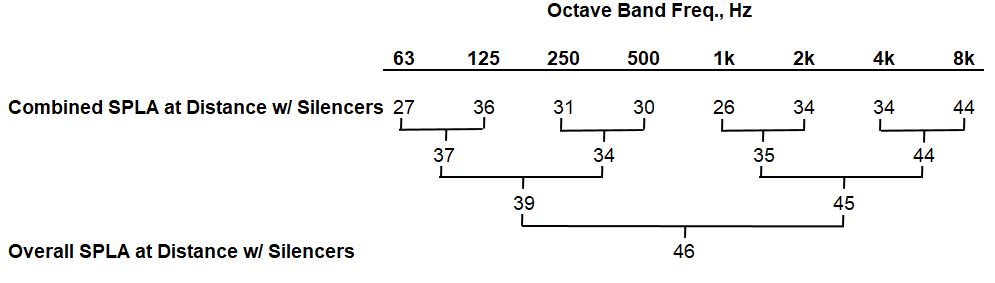

To determine if our sound reduction techniques meet the maximum noise limit of 50 dBA, the final step is the calculation of the overall SPLA:

The good news is that overall SPLA is 46 dBA, which is under the maximum limit. The diagram below shows completed system design with the acoustic hood, baffle silencer and supply fan.

Conclusion

I hope that you have learned a little bit about the science of sound and how we apply that science to meet acoustic requirements. At Eldridge, we have 75 years of experience with noise control applications and applying the science of sound. If noise is an issue in your facility, let an Eldridge noise control specialist help you create a safe and successful space for your employees.