When selecting the right propeller for an application, there are several important factors to consider. In this article, I’ll discuss propeller selection tips that you need to know the next time you are selecting a replacement propeller or one for a new fan.

Material

The most commonly used material for the blades of an industrial fan propeller is aluminum. It is the perfect material because it is light weight, heat tolerant and most importantly, it is easily cast into efficient airfoil shapes. It is the best fan blade material for most industrial applications.

When the airstream contains highly corrosive chemicals, it will be necessary to use either a fiberglass or stainless steel material. All wastewater treatment plants use fiberglass propellers for this reason. The downside to using stainless steel as a propeller material is that it is not easily shaped into an airfoil design therefore, stainless steel propellers are less efficient.

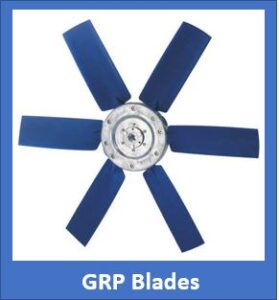

Glass reinforced plastic (GRP) is growing in popularity as a fan blade material. It is lighter weight than aluminum which means less horsepower to turn the propeller. The downside to GRP blades is that it can’t be used for temperature conditions above 160 degrees F. For simple comfort cooling applications, a propeller with GRP blades is your best value.

Fixed or Adjustable Pitch Blades

A propeller with fixed pitch blades means the blades are permanently attached to the hub in a fixed position. A propeller with adjustable pitch blades means that the blades can be adjusted after they are attached to the hub. The main reason why a propeller with adjustable pitch blades is more desirable is fan efficiency. Fixed pitch blades are often cast with blade pitch angles in 5 degree increments. Adjustable pitch blades can be accurately set with 1 degree increments. If you have an application that requires a 23 degree blade pitch, you may have to use a propeller with a fixed pitch of 25 degrees to get the required air flow. The additional pitch of 2 degrees will require more horsepower to turn the propeller making it less efficient than a propeller with adjustable pitch blades set to 23 degrees.

A propeller with fixed pitch blades means the blades are permanently attached to the hub in a fixed position. A propeller with adjustable pitch blades means that the blades can be adjusted after they are attached to the hub. The main reason why a propeller with adjustable pitch blades is more desirable is fan efficiency. Fixed pitch blades are often cast with blade pitch angles in 5 degree increments. Adjustable pitch blades can be accurately set with 1 degree increments. If you have an application that requires a 23 degree blade pitch, you may have to use a propeller with a fixed pitch of 25 degrees to get the required air flow. The additional pitch of 2 degrees will require more horsepower to turn the propeller making it less efficient than a propeller with adjustable pitch blades set to 23 degrees.

The Number of Blades

Increasing the number of blades on a propeller is most often used to increase the amount of air flow from a fan without increasing its diameter. However, increasing the number of blades also results in a louder fan. The sound created by a fan propeller is impacted by the distance between the blades and the blade pitch angle. Therefore, a 10 blade propeller will be louder at the same volume of air flow and speed compared to a 5 blade propeller of the same diameter.

Tip Clearance

When selecting a replacement propeller, it is important to allow for the proper amount of clearance between the tip of the blade and the fan housing. Too little distance and the blade may rub on the housing creating problems such as noise or a bend motor shaft. Too great a distance, and air will “leak” around the blade tip reducing the amount of air exhausted by the fan. The optimal tip clearance that we have used in the manufacturing of E-Fans is 0.25.”

Conclusion

Applying these propeller selection tips to the the selection of your next propeller should help you make a better decision. If you need more help with the propeller selection process, contact Eldridge and one of our ventilation experts will assist you with the right selection.