Centrifugal fans or blowers have a wide variety of process air applications. When selecting a centrifugal fan wheel for a particular application, here are three most common types to choose from:

- Forward Inclined

- Backward Inclined

- Radial

In this week’s blog, I will discuss the characteristics of each type of wheel and the applications for which each is best suited.

Air Flow Characteristics

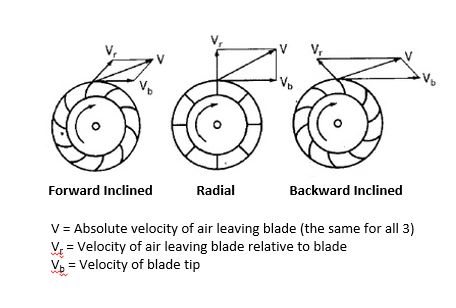

We will start with the airflow characteristics of each type of wheel since this is what matters for determining its suitability for an application. The three diagrams below show the direction of airflow coming off the blades.

The diagrams show that the air leaving the blades of the radial and backward blades is in a radial direction whereas the air leaving the forward inclined wheel is in a tangential direction. The diagram also shows that to produce the same absolute air velocity, the tip speed of the forward inclined wheel is the lowest.

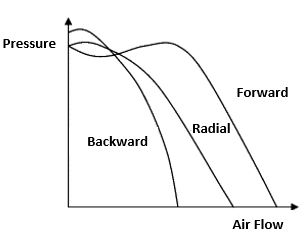

Now let’s look at the relative performance of the three types of wheels given these air flow characteristics:

At medium to high pressures and low flow rates, the backward inclined and radial wheels perform the best. At medium to high pressure and low flow rates, the forward inclined wheel is actually unstable. It is best suited for low pressure and high volumes.

Applications

Forward inclined wheels are best suited for applications that need a constant flow of air under low static pressure conditions. Because forward inclined wheels will overload, they are not recommended for variable flow applications. One of the best characteristics of a forward inclined wheel is that it will produce the same volume of air at lower at a lower speed compared to backward inclined or radial wheels, therefore it is much quieter. For these reasons, the forward inclined wheel is widely used in residential and commercial air conditioning. Other applications include oven and dryer exhaust, and process drying and cooling.

Radial bladed wheels are best suited for medium pressure and medium volume applications with steady flow requirements since they also will overload. Because the wheels can be ruggedly constructed, they are good for applications where the air flow is corrosive or contains materials. Applications include conveying powdery or granular material and long stringy paper trimmings or fibers.

Backward inclined wheels are more energy efficient than the other two types of wheels and with curved or airfoil style blades, they can come close to the efficiency of an axial fan. Backward inclined wheels will not overload or stall and are well suited for variable flow applications. Common applications include dust collectors, fume exhausters and emission control systems.

Conclusion

Making the right choice in a centrifugal fan means selecting the best wheel for the application. In our 75 years of creating successful environments, Eldridge has helped many customers make the right choice for unique applications such as wind tunnels, railcar dryers and heavy gas fume extraction systems.