Spot cooling fans are an excellent way to provide additional comfort cooling for people working in geographical areas where the outdoor temperature is above 77ºF. These fans work by moving air across a person that results in an increased sweat evaporation rate. The key to successfully utilizing spot cooling fans is knowing how to place them in locations so that they provide sufficient air movement. This means knowing how to determine the Spread and Throw for the fans. In this article, I will go through the math behind Spread and Throw calculations and provide an example of how to apply them.

Spread

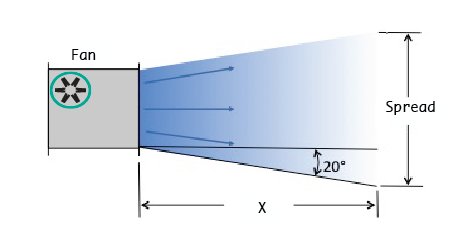

Let’s begin with defining Spread: the width of the divergence of the air stream measured in either a horizontal or vertical plane

Think of the air flow from a fan expanding to form a cone of air movement. The figure below illustrates the cone shaped air flow.

The angle of the outer boundary of the air flow relative to the side wall of the fan is 20º regardless of the air flow volume from the fan. Therefore, the formula for calculating Spread:

Where:

D = Diameter of the fan

X = Distance from the fan outlet

Throw

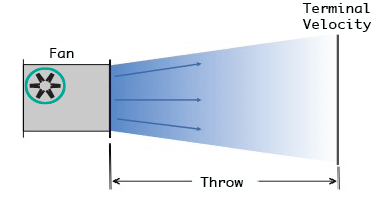

Throw defined as: the distance from the fan outlet to a desired average terminal velocity

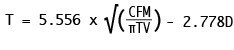

As opposed to Spread, Throw is dependent on the air flow volume from the fan. Throw is also dependent on the formula used to calculate Spread. Therefore, the complicated formula for Throw:

Where:

CFM = fan air flow volume

TV = desired average Terminal Velocity

D = Diameter of the fan

Application

For our application example, it is summertime in Texas and we have a person working in front of a machine that requires additional comfort cooling. The air change rate provided by the ventilation system in the building makes the inside temperature the same as the outside. Unfortunately, it is still above 77ºF for much of the workers shift. To achieve the desired comfort cooling effect that will keep the worker cool and productive, we recommend using a spot cooling fan to create air movement at 200FPM where the worker will be standing.

Now assume that we have a 36” diameter spot cooling fan that has a flow rate of 10,000 CFM. Using the Throw formula, we can determine that the spot cooling fan will need to be placed 13.8 feet from the worker to provide an average of 200 FPM of air movement. Using the Spread formula, the diameter of the cone of air at a distance of 13.8 feet will be 8.0 feet. That will be sufficient to provide head to toe comfort cooling for the person working in front of the machine.

Conclusion

I hope this article has given you the knowledge and ability to go out into your facility and determine if your spot cooling fans are in the right location. If you don’t already have spot cooling fans for your workers, we recommend you should. Your investment will pay for itself with higher worker productivity. Eldridge can help you determine the best type of spot cooling fan for your application and we guaranty the proper and most functional placement.