Customers often ask which ventilation system is right for my facility? When Eldridge designs an industrial ventilation system, we do it considering that it needs to accomplish the main goal to exhaust heated or contaminated air from the facility and supply fresh, clean, and ambient temperature outside air. There are four ways that a ventilation system can be designed to exhaust and supply air:

-

-

- Powered exhaust and gravity supply;

- Gravity exhaust and powered supply;

- Powered exhaust and powered supply; and

- Gravity exhaust and gravity supply.

-

Determining which system is right for a facility depends on a number of specific factors of which the two biggest are the customer’s activities and the configuration of the building. Here is a brief overview of these four types of industrial ventilation systems including which applications each system is best suited for to accomplish the main goal.

Powered Exhaust and Gravity Supply

This type of system uses fans to exhaust air and gravity or natural air flow to supply air. When the exhaust fans are running, they create a vacuum or negative pressure in the building that draws the air inside. The typical configuration is to locate the exhaust fans on the roof or high on the walls and utilize the existing openings in the building, such as man or truck doors, to supply air. When there are not enough openings in the building to sufficiently supply air without creating a dangerous level of negative pressure, louvers are added around the perimeter of the building.

This is the most common and least expensive type of powered ventilation system because it can take advantage of the existing openings in a building. This is also the best type of system when there are conditioned offices connected to a building because the negative pressure keeps heat and contaminates out of the offices.

Gravity Exhaust and Powered Supply

For this system, fans located near the floor are used to supply air and ridge vents, hoods or louvers located on the roof or high on the walls allow the air to exhaust by gravity or natural air flow. The supply fans create a positive pressure in the building that pushes the exhaust air out of the building. In this case, it is best to keep man or truck doors closed or the air will short circuit and not exhaust the hot air at the top building.

The positive pressure provided by a gravity exhaust and powered supply system is best used where there is a need to have a clean air supply in the building and to keep contaminates out. Most food processing facilities use this type of system with filters on the supply fans.

Powered Exhaust and Powered Supply

This type of system uses fans on both the exhaust and supply side. The system can be designed to provide either a negative pressure or a positive pressure within the building by sizing either the exhaust or supply fans to provide more air flow.

This is the most expensive of the ventilation system types because of the cost for both exhaust and supply fans. The advantage is that it provides the most control over the location of where the air enters and exits a building. This is beneficial when a building requires a very high air exchange rate because the system won’t allow a dangerous level of either positive or negative pressure to occur when the fans are properly synchronized.

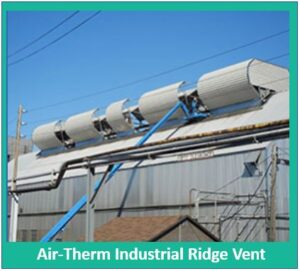

Gravity Exhaust and Gravity Supply

This system uses wind and the height of the building to create a natural flow of air. Because heat rises, a tall building can act like a chimney. It allows the warm air to rise-up and escape through the roof mounted openings. The rising air draws in supply air through the openings in the building at floor level. This rising air process is referred to as the stack effect. When the gravity supply openings are located on the windward side of the building, the wind significantly enhances this stack effect.

Although it is the least expensive type of ventilation system, the amount and dependability of the air flow is also the lowest. Locations where the prevailing winds are inconsistent or the wind speed is low, the air change rate inside the building may not be enough to provide an adequate level of comfort cooling.

Conclusion

Whether your project is a new build or retro fit, we hope that these brief overviews of each of the four types of industrial ventilation systems answers the question of which ventilation system is right for my facility. If you need additional help with your project, our ventilation system experts will make sure that the system is designed to meet your needs and accomplish your goal to create a better work environment for your employees.