History of Eldridge USA - Industrial Ventilation Installation

L.C. Eldridge Sales Co., Inc was established in 1946 by Len Eldridge in Dallas, Texas. The company got its start as a manufacturer’s representative for a number of quality U.S. manufacturers of fans, blowers, dampers, air filters, and silencers for airborne noise.

In 1952, Walter Leseman left Hydril and joined Eldridge. He relocated the company headquarters to Houston, Texas in 1956. Walt remained active in the company for 50 years until his retirement.

Walter and Len took a value-added approach to sales and we strive to embody that quality today across the various industries we serve.

Experience across industries

In the early years, our company’s primary emphasis was on upgrading the performance of cooling towers and heat exchangers with replacement fans in the refinery/chemical plant/gas transmission industries. Eldridge provided ventilation equipment for a wide range of general industrial, marine, and process air moving applications.

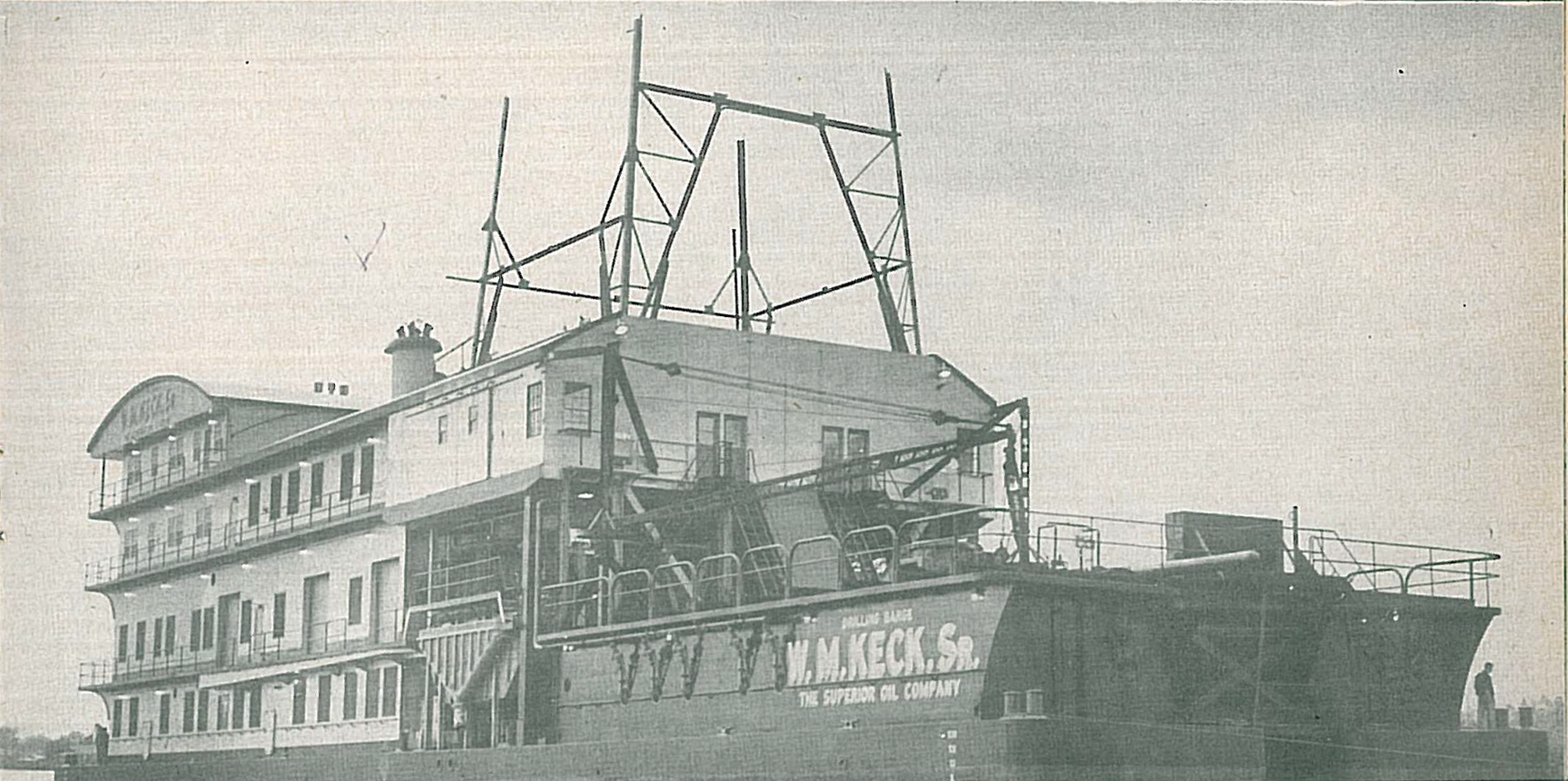

Eldridge pioneered methods of ventilating mobile offshore drilling rigs in the late 40’s/early 50’s, when the offshore drilling industry was in its infancy.

Throughout the 60’s and 70’s we provided ventilation systems to underground uranium, potash, and hard rock mines in the western US. New coal-fired power plants in New Mexico and Colorado required ventilation fans and pollution control dampers which Eldridge provided. Also, new build mobile offshore drilling rigs exploded on the scene with Eldridge providing below deck machinery space ventilation system designs and equipment.

The original company logo was retired in 2006.

When the Superior Oil Company built its state-of-the-art submersible drilling barge, “W.M. Keck, Sr.”, in 1953 at the Levingston Shipbuilding yard in Orange, Texas, Eldridge designed the ventilation system and supplied the fans. Originally published in “The Oil Forum” February 1953.

Eldridge provided safety-related, high integrity dampers on the South Texas Nuclear Project in the early 80’s. Ventilation and noise control upgrades on aging mobile offshore drilling rigs and production platforms were handled by Eldridge sales engineers during this time as well. Eldridge perfected a method to preserve stacked mobile offshore drilling rigs with desiccant dehumidification which maintained the integrity of this critical and expensive equipment during a severe energy recession.

This preservation method was so successful that ABS incorporated it into its guidelines for rig lay-up procedures.

The mid 80’s through 90’s, brought about a rapid increase package power projects. Eldridge participated in the design and ventilation of aero-derivative package power system, reciprocating engine power barges, and land-based reciprocating engine power installations. This work took us all around the world from Houston to Central America to Northern Europe and relied on Eldridge’s expertise in ventilation fans, high integrity CO2 and Halon isolation dampers, and stringent noise control systems.

Around 2000, there was another rapid demand and increase in building mobile offshore drilling rigs. Eldridge again designed ventilation, air volume control, and acoustic systems for this market and provide equipment on a significant number of new jack-ups, semis, and drillships. By 2010, over 70% of the active world fleet of mobile offshore drilling rigs were utilizing Eldridge designs and equipment.