It’s common knowledge that a hot workplace lowers worker output. The same holds true for a cold workplace setting. This blog will explore the science behind productivity decline in cold weather and what steps should be taken to safeguard workers.

Productivity Decline

When faced with cold temperatures, the human body starts to defend itself to maintain core heat. The first response is to limit blood flow to the extremities, preserving warmth in the body’s core and vital organs. That’s why we first notice the cold in our hands and feet.

As the body begins this defense against cold by restricting blood flow, an individual’s productivity starts to drop. A study by Thomas and Yiakoumis (1987) found that for various construction tasks, 50°F was the point where productivity began to decrease. Their findings show that for every degree below 50°F, productivity fell by over 1%. This means that at 40°F inside a facility, workers are only 90% productive.

Install Heaters

We suggest keeping industrial facilities at 50°F or warmer during cold weather. The most effective way to raise the indoor temperature and protect workers is by installing industrial heaters. The heat needed for an industrial heating setup will require determining the heat lost or gained from these factors:

- How much heat escapes through the building’s outer walls and roof?

- What amount of heat is lost through air being vented from the building?

- How much heat is lost through open doors, windows, and loading areas?

- What amount of heat is generated by activities (like welding) or equipment (such as ovens) inside the building?

The heat needed to raise the indoor air temperature from the average outdoor temperature to the desired level can be determined from the answers to these questions. For the average outdoor temperature, we advise using the ASHRAE 99% Heating Design Temperature for your area.

Heater Selection

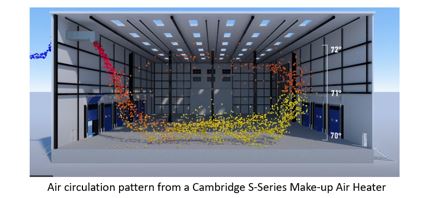

Facilities that need a large volume of make-up air due to ventilation needs for fresh air should think about using make-up air heaters. For facilities with little or no fresh air needs in cold weather, industrial space heaters are suitable.

Direct-fired gas heaters are the most efficient way to heat air. Compared to other heating methods, natural gas is plentiful and cost-effective. All of the heat from combustion goes straight into the incoming fresh air stream. Other methods can’t match this level of efficiency.

Place Your Order Now

While winter may seem distant, now is the time to order your heaters. We are the Texas and Louisiana representatives for Cambridge Air Solutions industrial heaters. Currently, their S-Series make-up air heaters and SA-Series space heaters have 4–6 week lead times. Factor in delivery and installation, and heaters ordered today will be operational in 8-10 weeks.

Conclusion

Whether you need help deciding if industrial heaters are right for your facility or you’ve already decided and just need sizing assistance, reach out to a ventilation expert at Eldridge. We’ll help you add heaters to boost worker safety and productivity during cold weather.