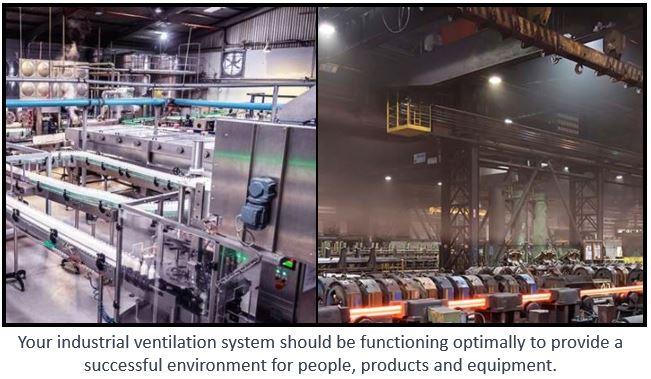

Industrial ventilation systems play a crucial role in maintaining a healthy and safe working environment by effectively controlling air quality, temperature, and airflow in industrial facilities. Regularly assessing these systems is vital to ensure they are functioning optimally to provide a successful environment for people, products and equipment. In this article, we will explore the key steps involved in assessing your industrial ventilation system, helping you identify potential issues.

Understanding the Importance of Assessment

Proper assessment of your industrial ventilation system is essential for two reasons. First, it helps safeguard the health and well-being of your employees by ensuring that indoor air quality is within acceptable limits, minimizing exposure to harmful contaminants. Second, assessing the system’s performance helps identify inefficiencies, such as improper airflow or inadequate filtration, which can impact employee productivity, product quality and equipment efficiency.

Assessment Process

For a complete assessment of your industrial ventilation system, follow this five-step process:

Step 1: Review System Design and Documentation: Thoroughly review the design specifications and documentation of your industrial ventilation system. This includes airflow patterns, air exchange rates, filtration efficiency, and other relevant details. Understanding the intended design will help evaluate the system’s performance and identify any deviations or shortcomings.

Step 2: Conduct an Inspection: Perform an inspection of the system’s components, including fans, filters, ductwork, exhaust hoods, and control devices. Look for signs of physical damage, corrosion, leaks, loose connections, or worn-out parts.

Step 3: Measure Airflow Rates and Ventilation Effectiveness: Utilize appropriate instruments such as anemometers or flow meters to measure airflow rates at different points in the system. Compare the measured airflow with the design specifications to ensure they align.

Step 4: Evaluate Air Quality: Assess the quality of the air being circulated within your facility. Conduct air sampling tests to measure the concentration of contaminants present. Compare these measurements to established permissible exposure limits (PELs) or threshold limit values (TLVs) to ensure compliance with safety guidelines. If the measurements exceed the limits, consider reviewing your filtration system or addressing potential contamination sources.

Step 5: Assess Noise Levels: Evaluate the noise levels generated by your ventilation system. Excessive noise can negatively impact employee comfort and productivity. Use sound level meters to measure and compare noise levels with acceptable limits specified by regulatory authorities. If noise levels exceed the limits, consider implementing noise reduction measures.

Conclusion

Regular assessment of your industrial ventilation system is crucial for maintaining a healthy and safe working environment. By following the steps outlined above, you can effectively evaluate the performance of your system and identify any deficiencies. If you would prefer to have your system assessment performed by a ventilation expert, call us at Eldridge. We will provide a complete assessment and recommend what should be done to correct any issues.