In the food processing industry, sanitation is paramount to prevent contamination and maintain high levels of food quality and safety. Traditional cleaning methods can be time-consuming, costly, and will leave behind harmful residues. That’s where CASPR (Continuous Air and Surface Pathogen Reduction) comes in as the best way to sanitize a food processing facility. In this article, we will explore what is CASPR and why it is the best food processing facility sanitation solution.

What is CASPR?

CASPR uses proprietary technology to combine UV light, a catalyst, and moisture in the air to generate negatively charged hydrogen peroxide ions. These molecules exit the air duct, circulate the facility through the air and land on all surfaces that are exposed to air. During this process, these negatively charged hydrogen peroxide molecules are actively seeking out positively charged molecules, like mold, bacteria, and viruses, to neutralize by killing at the molecular level. Documented studies have proven CASPR to be 99.96% effective against killing these pathogens in the air and on all surfaces.

Is Hydrogen Peroxide Safe?

Hydrogen peroxide can be found in trace amounts in the air that we breathe. Ever stepped outside after a thunderstorm and marveled at how fresh the air smells? That’s thanks to ionized hydrogen peroxide in the air that is generated by lightening.

The food processing industry already uses hydrogen peroxide to sterilize some food packaging and containers. Also, hydrogen peroxide is an FDA approved food additive. It is found in toothpastes and mouthwashes.

Benefits of CASPR for Sanitizing Food Processing Facilities

- Continuous Sanitization: Most importantly, CASPR technology is working 24/7, even when employees are present, to maintain a safe and clean environment. After surfaces have been touched by food products or humans, the hydrogen peroxide in the air lands on the touched surface and neutralizes any pathogens that may have been left behind.

- Actively Eliminates Pathogens: HEPA filters and UV light must passively wait for pathogens to be brought to them. The negatively charged hydrogen peroxide ions generated by CASPR are actively seeking positively charged pathogens in the air and on all surfaces that have been exposed to air.

- Cost-Effective: CASPR technology is cost-effective, requiring no expensive chemicals or labor-intensive cleaning procedures. It also has a low maintenance cost, making it an affordable solution for small and large food processing facilities.

- Improved Indoor Air Quality: CASPR technology not only eliminates pathogens but also improves indoor air quality. It eliminates unpleasant odors and reduces airborne contaminants, creating a more pleasant and healthier working environment.

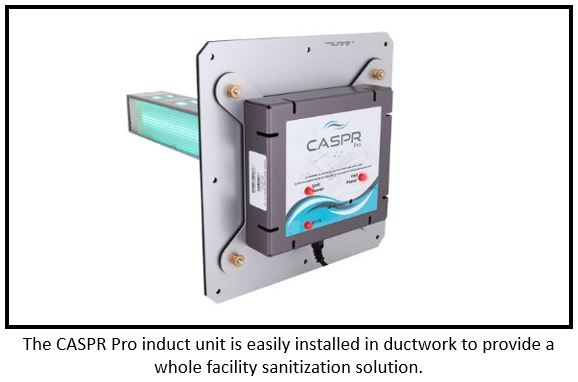

- Easy to Install and Use: CASPR technology is easy to install and use. It requires no major modifications to existing HVAC systems and can be easily integrated into any food processing facility. It also requires no special training or certification to operate.

Conclusion

CASPR’s proprietary technology is the best way to sanitize a food processing facility. It is an innovative solution that can help food processing facilities maintain high levels of food quality and safety while reducing the risk of contamination and the need for costly and time-consuming traditional cleaning methods. If you want to use the best sanitization solution in your food processing facility, contact a ventilation specialist at Eldridge.