Cold storage facilities can be plagued by condensation or ice build-up problems brought about by too much moisture in the air. These problems can be exacerbated in the summer months when the moisture level in the outside air is double or triple what it is in the winter months. Eldridge has helped many customers eliminate condensation or ice build-up problems in their facilities resulting in improved worker safety, higher product quality and better equipment efficiency. We will start this two part series by discussing the ways of determining the moisture load on a cold storage facility.

Moisture Load

All moisture that enters a cold storage facility is referred to as the moisture load. The primary sources of moisture coming into a cold storage facility are: penetrations, people, products and infiltration. We will go through how we assess the contributions to the overall moisture load from each of these sources.

Penetrations

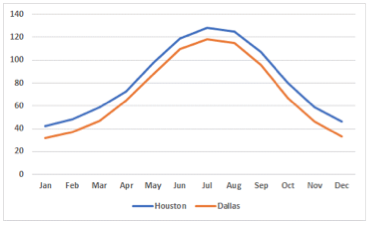

Penetrations are the openings, such as people and lift truck doors, where outside air may enter. These are usually the greatest source of moisture coming into a cold storage facility. To calculate the moisture load from such penetrations, we first need to determine the number of times and the duration that the doors are open. Secondly, we need to know the moisture content of the air surrounding these doors. If it is unconditioned space, we can use the average moisture content of the outside air at the facility’s location. The chart below shows the average moisture content by month, in grains per pound, of outside air for Dallas and Houston. We are able to calculate the average moisture content of outside air from average temperature and relative humidity data using a psychrometric chart.

The peak moisture content of the air for Dallas and Houston is in the summer months. This is also true for most areas around the Gulf Coast. When determining the amount of moisture load contributed by penetrations, we will use the peak moisture content of air at the facility’s location to properly size any solution that we recommend.

People

When people sweat or exhale, they are giving off moisture. This adds to the moisture load in a cold storage facility. The number of people that enter and the amount of time that they spend inside the facility needs to be determined. Additionally, we would need to know the activities that the people are performing. Persons performing more strenuous activities give off more moisture.

Products

Products in a cold storage facility can be a source of moisture in two ways. First is from the product itself. Some products may give off moisture because of the vapor pressure between the product and the air. For example, unpackaged plant products will give off moisture through natural respiration even after they reach the temperature inside the cold storage facility. The second source of moisture is condensation on products. As product passes from truck to loading dock to cold storage, condensation will develop if exposed to air that is warmer than the product.

Infiltrations

An important factor to consider is the material used to construct the floors, walls and ceilings of the cold storage facility. These can be a source of infiltration even if there are no obvious cracks or leaks. Insulated metal panels will allow the least amount of infiltration where drywall and concrete allow the most. The amount of moisture infiltration through the walls and ceilings will depend on the amount of moisture in the surrounding air. Ideally, all door seals and gaskets should be working effectively to prevent any infiltrations. If not, they should be replaced so as not to contribute to the moisture load. As with penetrations, we use the peak moisture level of the surrounding air to estimate the moisture load from infiltration.

Solutions

Once we have an understanding of the amount and sources of the moisture load, we can begin to evaluate which solutions will work best for a customer’s particular moisture problem in a cold storage facility. Join us next week for Part 2 of this series as we go though the process of evaluating potential solutions.