In Part 1 of this two part article on Cold Storage Moisture Problems, we identified the four primary sources of moisture in cold storage facilities. I will conclude this series with Eldridge’s solutions for solving condensation or ice build-up problems.

Minimizing Moisture Load

Whether our customer is asking for help with problems in their facility or designing a new facility, we begin with an analysis of the moisture load. This provides the sources and amounts of moisture going into a cold storage facility. From this analysis we can suggest the best solutions to minimize moisture load in each of the four primary sources identified in Cold Storage Moisture Problems Part 1.

Penetrations

Penetrations

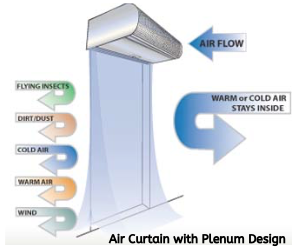

When either man or lift truck doors are expected to be opened frequently and stay open for long periods, an air curtain is a great solution. It offers the dual solution of preventing moisture laden outside air from coming in and cold inside air from going out. The most effective air curtains have a plenum design that provides an even flow of air across the door opening.

Bi-parting swinging doors are also a good solution for high traffic man doors. The design minimizes the amount of area for air to pass through and will close automatically thus reducing the duration of exposure. When budgets are tight, a strip curtain can be a low-cost alternative.

People and Products

We don’t have any recommendations for equipment that will minimize moisture load from people and products in a cold storage facility. However, we do recommend that cold storage areas be well-organized with signs or diagrams indicating where different products are stored as one way to minimize the amount of time people spend placing or retrieving products.

Infiltrations

New cold storage facilities should be designed with thermally insulated walls and ceilings that will also have a vapor barrier on the outside. Existing facilities without a vapor barrier or one that has not been properly sealed should have a new thermally insulated vapor barrier installed.

Eliminating Moisture Load

After all of the solutions to minimize moisture load have been applied, we can recommend solutions to deal with the remaining moisture load. The best and really the only effective way to eliminate the remaining moisture load in a cold storage facility is with a desiccant dehumidifier. The advantage of a desiccant dehumidifier is that it can achieve extremely low dew points that can’t be achieved with refrigerant style dehumidification. It is also the most cost-effective way to maintain relative humidity levels below 45% in refrigerated warehouses.

After all of the solutions to minimize moisture load have been applied, we can recommend solutions to deal with the remaining moisture load. The best and really the only effective way to eliminate the remaining moisture load in a cold storage facility is with a desiccant dehumidifier. The advantage of a desiccant dehumidifier is that it can achieve extremely low dew points that can’t be achieved with refrigerant style dehumidification. It is also the most cost-effective way to maintain relative humidity levels below 45% in refrigerated warehouses.

Conclusion

Eldridge’s experience has allowed us to customize solutions to fit each of our customer’s application and budget with a three-step process – Analyze, Identify & Utilize:

- Analyze moisture load sources and amounts

- Identify ways to minimize the moisture loads

- Utilize desiccant dehumidification to eliminate remaining moisture

All customized solutions provided by Eldridge feature high quality equipment manufactured by Innovate Air Technologies and Berner International. If you are designing a new cold storage facility or have problems with an exiting one, let an Eldridge expert customize your solution to moisture and ice build-up problems.