Most everyone understands that a hot working environment decreases worker productivity. The same is true about a cold working environment. In this article, I’ll go through the science of why cold weather reduces productivity and what should be done to protect workers.

Decreased Productivity

When exposed to cold temperatures, the human body begins a defense to conserve body heat. The first thing that the body does is restrict blood flow to the extremities to preserve heat in the body core and vital organs. That is why our hands and feet are where we first notice the effects of cold temperatures.

When the body starts a defense against cold temperatures by restricting blood flow, the productivity of an individual begins to decline. Workers performing a variety of construction related tasks found that 50º F was the point where productivity began to decline according to a study by Thomas and Yiakoumis (1987). Their data shows that the productivity decline was over 1% for every degree under 50º F. That means that when it is 40º F inside a facility, people working inside are only 90% productive.

Add Heaters

We recommend that industrial facilities be maintained at 50º F, or higher, during cold weather. The best way to increase the inside temperature of a facility and protect workers is by adding industrial heaters. To determine the amount of heat required for an industrial heating application, you will need to calculate the amount of heat lost or gained from these factors:

- How much heat is lost through the exterior walls and roof of the building?

- What amount of heat is lost through any air that’s being exhausted from the building?

- What amount of heat is lost through open doors, windows, and loading docks?

- How much heat is produced by activities (i.e. welding) or equipment (i.e. ovens) inside the building?

The heat required to increase the inside air temperature from the average outside air temperature to the desired air temperature can be calculated from the answers to those questions. For the average outside temperature, we recommend that you use the ASHRAE 99% Heating Design Temperature for your location.

Heater Type

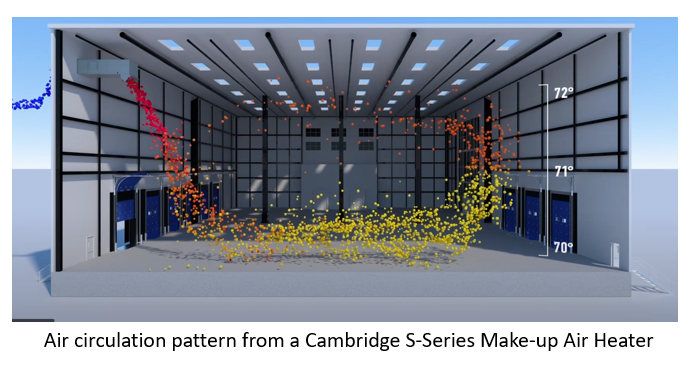

Facilities that require a significant volume of make -up air because of ventilation requirements for fresh air should consider using make-up air heaters. For facilities that have little or no fresh air requirements in cold weather can use industrial space heaters.

Direct fired gas heaters are the most efficient way of heating air. Compared to other heating methods, natural gas is abundant and inexpensive. One hundred percent of the heat of combustion goes directly into the incoming fresh air stream. Other methods don’t come close to this level of efficiency.

Order Now

The cold weather season may seem like it is months away. However, the time to place your heater order is now. The lead time for many manufactures have been increasing due to labor and material shortages. We represent Cambridge Air Solutions for industrial heaters in Texas and Louisiana. Their current lead times are running 8-10 weeks for both the S-Series make-up air heater and their SA-Series space heaters. You will also need to factor in delivery and installation. With an order placed today, the total time until the heaters are operational is 12-14 weeks.

Conclusion

Whether you need more help deciding if industrial heaters are right for your facility or if you have decided already and just need to size them for your facility, contact a ventilation expert at Eldridge and we will assist you with adding heaters to protect workers and increase productivity during cold weather.