Cold storage facilities play a critical role in preserving and storing various perishable goods such as food and pharmaceuticals. However, these facilities face numerous challenges, including high humidity levels that can lead to condensation, mold growth, corrosion, and spoilage. To address these issues, many cold storage facilities are turning to desiccant dehumidification systems, which offer several benefits over traditional refrigeration-based dehumidifiers.

In this article, we will explore why moisture is a problem in a cold storage facility, the basics of desiccant dehumidification, and why it is an effective solution for cold storage facilities.

Why is Moisture a Problem in a Cold Storage Facility?

Moisture is a problem in a cold storage facility for several reasons:

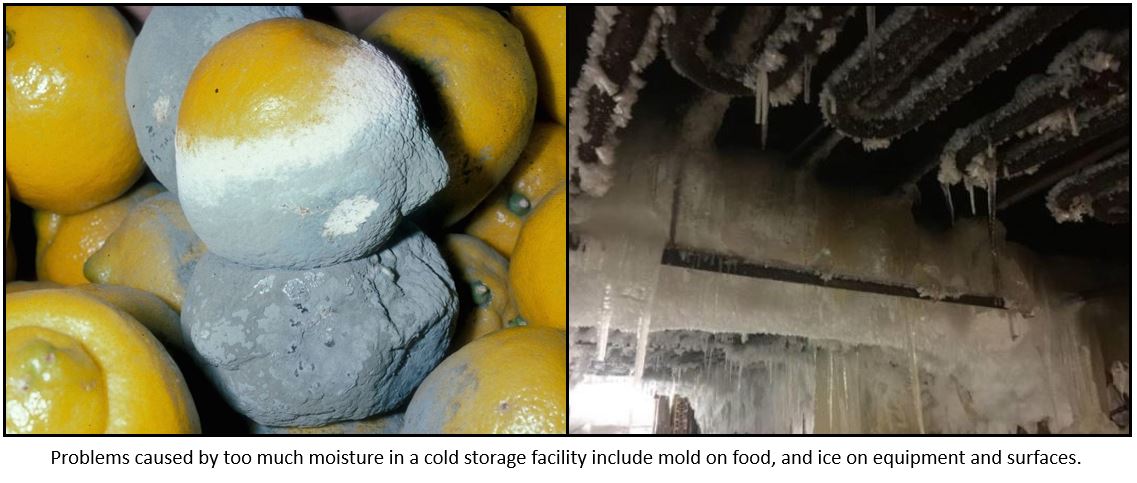

- Product quality: Many perishable products such as food, pharmaceuticals, and other goods are sensitive to moisture. High levels of moisture can cause products to spoil, deteriorate, and lose their quality. For example, moisture can cause food to develop mold, bacteria, and other pathogens that can lead to foodborne illnesses.

- Safety concerns: High levels of moisture in a cold storage facility can create a slippery floor surface, increasing the risk of falls and other accidents. Moisture can also create condensation on the surfaces of the facility, leading to the growth of mold and mildew, which can be a health hazard for workers.

- Equipment damage: Moisture can cause damage to equipment such as compressors, motors, and other electrical components in a cold storage facility. This can lead to costly repairs and downtime, affecting the efficiency and productivity of the facility.

- Energy consumption: When moisture is present in a cold storage facility, refrigeration equipment must work harder to maintain the desired temperature. This can result in higher energy consumption, leading to increased costs and environmental impact.

What is Desiccant Dehumidification?

Desiccant dehumidification is a process that involves using a desiccant material to remove moisture from the air. A desiccant is a substance that has a high affinity for water molecules. That means it can absorb moisture from the air and hold it within its structure. The most common desiccants used in dehumidification systems are silica gel and activated alumina.

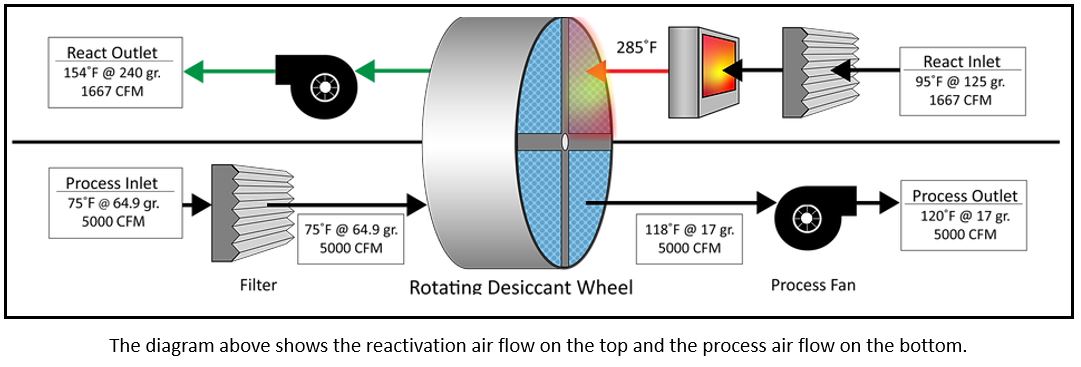

Desiccant dehumidification works by passing moist air over a desiccant material, which absorbs the moisture from the air. The desiccant material is then regenerated by heating it as it turns past the React portion of the wheel. The heated air flowing through the wheel drives off the moisture and restores its capacity to absorb more moisture. The dry air is then discharged into the cold storage facility through the Process Outlet, reducing the humidity levels and preventing condensation.

Why Use Desiccant Dehumidification in Cold Storage Facilities?

Desiccant dehumidification offers several benefits over traditional refrigeration-based dehumidifiers, including:

- Prevent moisture buildup: Desiccant dehumidifiers remove moisture from the air. That prevents the buildup of condensation on the surfaces of the stored products. This helps to prevent mold and mildew growth, which can damage the products and create an unhealthy environment.

- Maintain product quality: The proper level of humidity is critical to maintaining the quality of perishable products. Desiccant dehumidification helps to regulate the humidity levels, ensuring that the products remain fresh and do not spoil.

- Increased storage capacity: By maintaining the proper humidity levels, desiccant dehumidification can help increase the storage capacity of cold storage facilities. This is because it prevents moisture buildup, allowing products to be stored closer together without the risk of damage.

- Low dew point capability: Desiccant dehumidifiers can achieve very low dew point temperatures, which is crucial in cold storage facilities where maintaining low humidity levels is essential to prevent spoilage and corrosion.

- Flexibility: Desiccant dehumidifiers can operate in a wide range of temperature and humidity conditions. That makes them suitable for various cold storage applications.

- Reduced maintenance: Desiccant dehumidifiers have fewer moving parts and require less maintenance than refrigeration-based dehumidifiers, reducing downtime and repair costs.

Conclusion

Desiccant dehumidification is a reliable and efficient solution for maintaining low humidity levels in cold storage facilities. Eldridge partners with Innovative Air Technologies to design and supply desiccant dehumidification systems for any cold storage application. If you are considering installing a desiccant dehumidification system in your cold storage facility, consult with a ventilation expert at Eldridge to determine the best solution for your specific needs.