The summer of 2022 saw extreme heat across most of the US. NOAA data shows that over 170 million Americans were under an extreme heat watch or warning this summer. All forecasts point to the extreme heat getting worse not better. This means that employers with outside workers and factories with unventilated or under-ventilated systems will need to do more to protect workers from the extreme heat. If your company is one that needs to do more to protect workers from extreme heat, now is the time to develop a strategy for a cooler 2023.

Hot Future

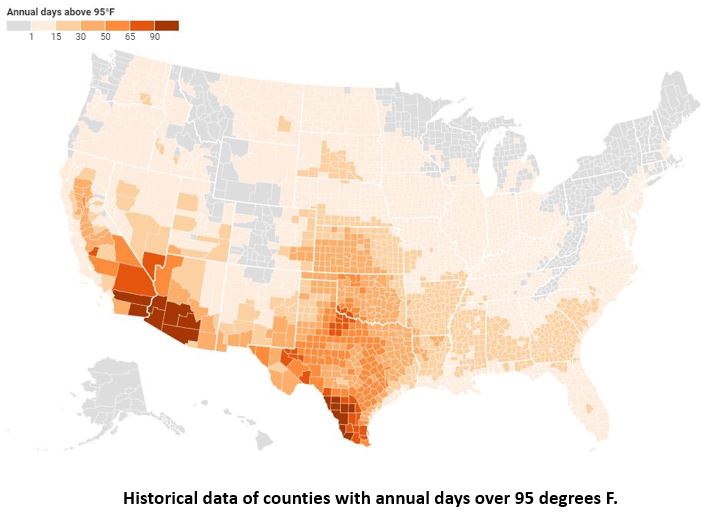

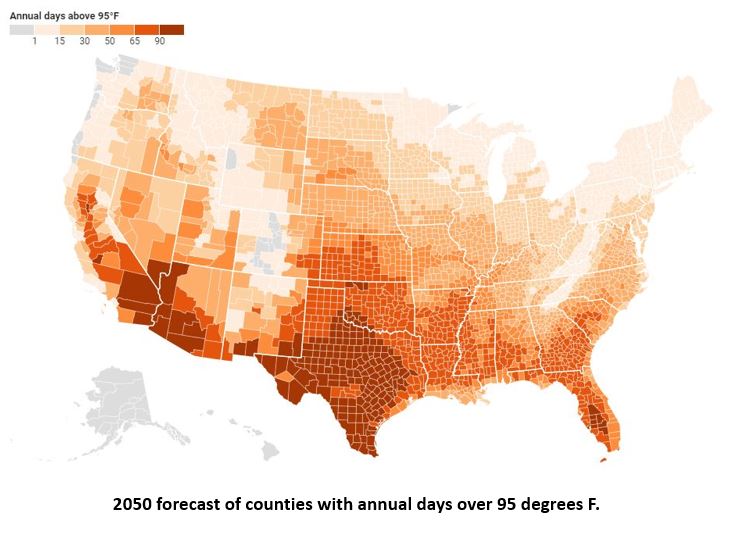

To understand the potential spread of the extreme heat across the US, look at the two maps below. They are from the US Global Change Research Program. The first is the historical look at counties with the annual number of days above 95 degrees F. The second is the forecast of the number of days above 95 degrees F in 2050.

Impact on Outside Workers

What does this mean for companies with outside workers? It means that there will be a dramatic increase in the costs related to these factors:

- Lost productivity

- Employee turnover

- Employee absenteeism

- Heat related worker compensation claims

I want to focus on lost productivity since it will become the largest cost to employers. Studies have found that worker productivity decreases by 1% for every 1 degree F increase in the temperature over 77. That means when the temperature is 95 degrees F outside, workers are only 82% efficient. Now look at the 2050 forecast map and you’ll see that there only a few areas in the country that won’t face the problem of lost productivity.

Strategies for a Cooler Workplace

The first step in creating a cooler workplace is to remove the solar heat load inside the facility. Solar heat load is the result of the sun light heating up the roof and that heat transferring to the inside. Without proper ventilation, the heat will eventually build all the way to the floor level. By designing a ventilation system with an adequate number of air changes per hour, the solar heat load will be removed, and the inside temperature of the facility will be close to the same as the outside temperature.

The next step will be to provide spot cooling or HVLS fans. While these fans don’t change the temperature of the air. Instead, the air movement that they create will cause sweat to evaporate. Depending on the humidity level, the perceived decrease in temperature caused by sweat evaporation is in the range of 8 to 10 degrees F.

The final step is to consider reducing the temperature of the air inside the facility. Air conditioning (AC) is the solution that most people think of when talking about cooling a facility. However, AC is expensive for both the capital and operating costs. A great alternative to AC is direct or indirect evaporative cooling. Direct evaporative cooling is best suited for low humidity areas like the Southwest. Indirect evaporative cooling doesn’t increase humidity, so it works best in areas where the daytime humidity levels are above 40%. Both direct and indirect evaporative cooling have significantly lower operating costs compared to AC.

Getting Started

To develop a strategy for a cooler 2023 you need to start with determining the best solution to provide heat relief for your employees. Eldridge ventilation experts have the experience and know how to determine what is the right solution for your facility. We can even help you justify the cost of a ventilation system upgrade by quantifying the payback that will come with improved productivity. Call Eldridge today to develop a strategy for a cooler 2023 and create a successful environment in your facility.