One of our customers needed help with the design, equipment selection, and installation of a dust collection system. Their current system was in adequate for their operations, and they needed an entirely new system to meet safety standards. The critical part of the process was to properly design the collection system. In this blog, I’ll go through the process of dust collection system design that we used to provide the right system for the customer’s application.

Customer’s Application

Our customer was a third-party packager of a variety of sugar products. They had a hazardous dust analysis performed that recommended an upgrade to their dust collection system to meet safety standards. In dust form, sugar can be highly explosive. In 2008, the Imperial Sugar factory in Georgia exploded killing 14 people. That very unfortunate incident has made all companies involved in manufacturing and packaging sugar products highly sensitive to having the right dust collection system for their specific application.

Design Collaboration

The most critical step in the dust collection system project was design. However, it was important to have all phases of the project, design, equipment selection, and installation covered by experts. On this project, we worked with Donaldson Torit for equipment and Dust Collection of Texas for installation. The design phase was a very collaborative and iterative process. All three parties contributed to the best and final design.

Design Process

Identifying the properties of the dust to be collected is the first step in any dust collection design. We were dealing with highly explosive sugar dust in this case. This allowed the team to determine, capture velocity, transport velocity, and explosion protection for the dust collection system.

The next step was to design the capture hoods. With an explosive dust, it was important to locate the capture hoods as close to the source. That minimize the potential for any escaping dust. This involved working with the customer to locate the hoods for the best capture efficiency without interfering with operations. Now knowing the hood size and number of capture points, we could determine the total airflow required for the system.

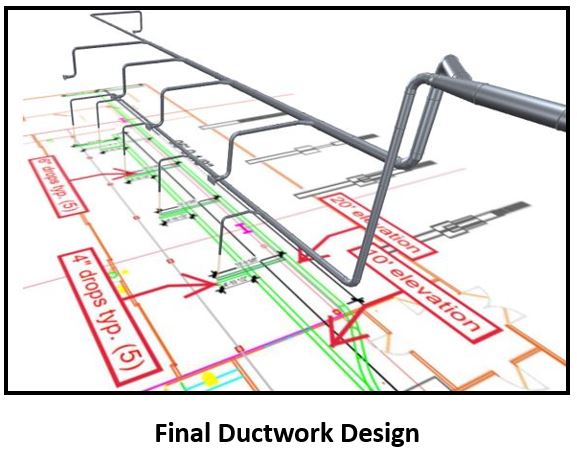

The third step in the process was to design the ductwork. The total required air flow and the transport velocity determines the ductwork size. The key to making sure that every branch to a capture point has the right capture velocity is determining where to design transitions into the main ductwork. Without transitions, the first few pick-up points will not effectively capture the explosive sugar dust. The other benefit to properly designing transition points is that it eliminates the need to add the cost of balancing dampers to each pick-up point.

The third step in the process was to design the ductwork. The total required air flow and the transport velocity determines the ductwork size. The key to making sure that every branch to a capture point has the right capture velocity is determining where to design transitions into the main ductwork. Without transitions, the first few pick-up points will not effectively capture the explosive sugar dust. The other benefit to properly designing transition points is that it eliminates the need to add the cost of balancing dampers to each pick-up point.

The final step in the design process was to determine the total system static pressure. The process to determine the total system static pressure involves calculating the pressure drop associated with each capture point, branch length, transition point, and elbow. Accurate determination of the total system static pressure is critical to fan selection. Underestimating total system static pressure would have resulted in lower than required airflow which means the explosive sugar dust would not have been properly captured.

Equipment Selection and Installation

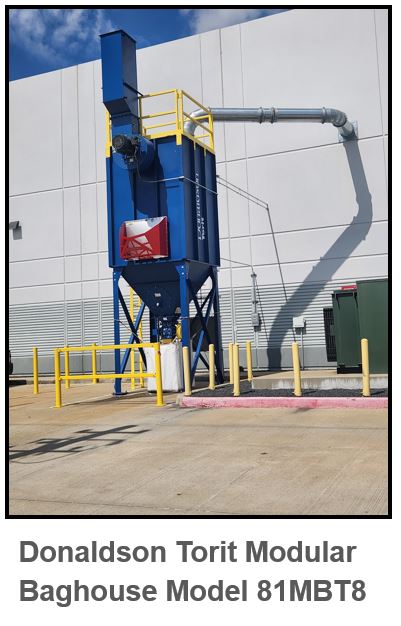

Donaldson Torit determined which fan and dust collector was needed to meet the airflow, static pressure, filtration, and explosion protection requirements. They also recommended that the dust collector be located outside of the building as part of the explosion protection requirements. This meant that we needed to determine how to provide filtered make-up air for the amount that the dust collector was pulling out of the building.

Donaldson Torit determined which fan and dust collector was needed to meet the airflow, static pressure, filtration, and explosion protection requirements. They also recommended that the dust collector be located outside of the building as part of the explosion protection requirements. This meant that we needed to determine how to provide filtered make-up air for the amount that the dust collector was pulling out of the building.

The capture hoods, ductwork and dust collector were expertly installed by Dust Collection of Texas. The last step for the whole project was confirming that we had the proper capture velocity at each of the pick-up points.

Conclusion

Our customer was very pleased with all phases of the project. They are now compliant with all safety standards for capturing explosive sugar dust.

Designing an effective dust collection system is a nuanced process, necessitating the collaboration of design, equipment selection and installation. Eldridge has the expertise and experience of leading teams in the process of finding the best solution for a specific dust collector application. When you need to upgrade your dust collection system, contact a ventilation expert at Eldridge and we will find the best solution for your application.