Water treatment facilities play a crucial role in ensuring the safety and availability of clean water for various applications, including drinking, irrigation, and industrial processes. However, these facilities face several challenges, including corrosive environments that can damage equipment, harm people, and compromise the quality of the treated water. To address these challenges, many water treatment facilities have turned to fiberglass fans, which offer several benefits over metal fans. In this article, I’ll explore the basics of fiberglass fans and why fiberglass fans are an effective solution in water treatment facilities.

What are Fiberglass Fans?

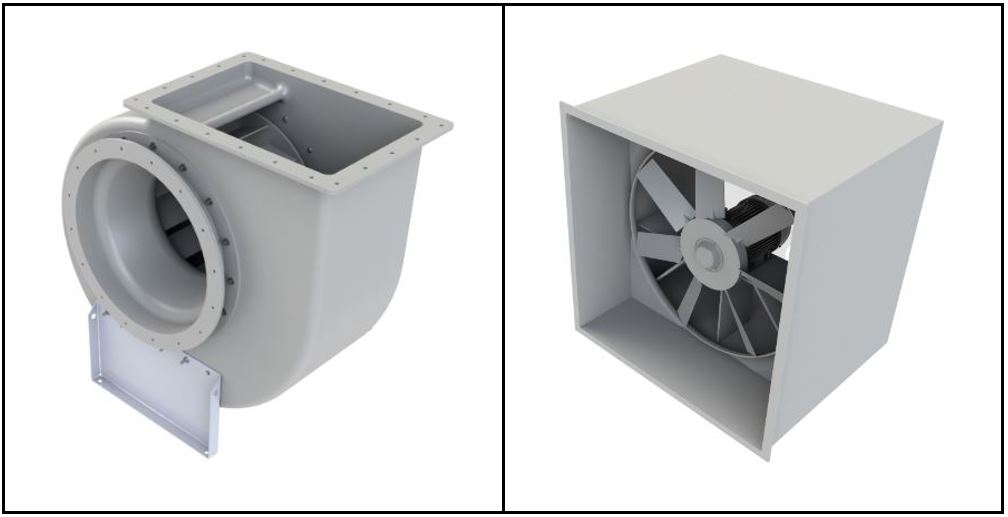

Fiberglass fans are industrial fans that feature blades and housings made of fiberglass-reinforced plastic (FRP). FRP is a composite material made of a thermosetting resin, such as polyester or epoxy, reinforced with glass fibers. FRP is a lightweight and durable material that offers excellent resistance to corrosion, chemicals, and UV radiation.

Why Use Fiberglass Fans?

Fiberglass fans offer several benefits over traditional metal fans, including:

- Corrosion resistance: Fiberglass fans are highly resistant to corrosion. That makes them ideal for use in environments where exposure to corrosive gases and liquids is common. Regardless of the alloy, metal fans can corrode and degrade over time, leading to reduced efficiency and increased maintenance costs.

- Chemical resistance: Fiberglass fans can withstand exposure to a wide range of chemicals commonly used in water treatment processes, including chlorine, ozone, and acids. This chemical resistance reduces the risk of fan failure and ensures the quality and safety of the treated water.

- Lightweight: Fiberglass fans are lighter than metal fans. This lightweight attribute reduces stress on the internal bearings and shaft. It also reduces maintenance and extends the service life of the fan.

- Spark-resistant: Fiberglass fans meet the AMCA Type A requirement for spark resistant. That is because all parts of the fan are made of non-ferrous materials. To minimize static electricity, graphite or a carbon synthetic veil is added to the corrosion barrier and a grounding lug is attached to the housing.

VPC Fiberglass

For fiberglass fan applications, we offer the entire product line from VPC Fiberglass. They have been making fiberglass fans in the US for over 30 years. Many of those fans are still operating today.

Primarily known for their quality and excellent lead times, VPC is also a leader in fiberglass fan technology. They have perfected the use of hollow blade manufacturing which means their axial fan propellers are some of the lightest in the industry.

In addition to fans, they also offer fiberglass ductwork, louvers, dampers, and enclosures. They are able to manufacture an entire fiberglass ventilation system from pick-up point to exhaust stack.

Conclusion

Fiberglass fans are a reliable and efficient solution for water treatment facilities that require corrosion-resistant, chemical-resistant, lightweight, and spark-resistant fans. Fiberglass fans will ensure the integrity and safety of equipment and people as well as maintaining the quality and availability of clean water. If you are considering adding new or replacing existing fans in your water treatment facility, consult with a ventilation expert at Eldridge to determine the best fiberglass fan solution for your specific needs.