Electric motors are becoming the preferred choice for gas pipeline compressor stations. But how do you keep a 20,000 horsepower electric motor cool? We’ll discuss two of the factors that must go into the proper design of an air based motor cooling system to keep these large electric motors running efficiently.

Removing Heat Load

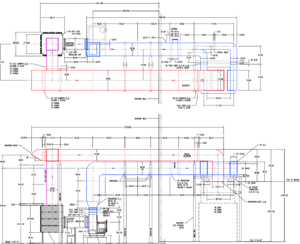

An electric motor generating 20,000 horsepower also generates a significant amount of heat. Above a certain temperature, the performance of an electric motor decreases. The difference between the desired maximum motor temperature and peak ambient temperature where the motor will operate is referred to as the Delta T. To keep the electric motor temperature within the Delta T limits, the cooling system air flow must be sufficient to remove the heat generated when the motor is operating at peak horsepower. A thermal heat transfer equation that uses the Delta T and the electric motor heat load can be used to calculate the required air flow for the cooling system.

Reducing Noise

Gas pipeline compressor stations must now comply with strict noise abatement requirements. The fan needed for an electric motor cooling system may generate more noise than the required limit. If so, the best way to reduce fan noise is to add a silencer in the air stream. However, sizing the silencer requires knowing how to determine the combined effect of the fan noise and the electric motor noise. When the sound power levels from these two sources are equal at an octave band, the required sound abatement by the silencer is greater than if there was only a single sound source. Failing to correctly calculate the combined sound power levels may result in under sizing the silencer and a failure to comply with the noise abatement requirements.

At Eldridge, we know that the investment in a gas pipeline compressor station utilizing an electric motor is significant. Without a properly designed motor cooling system, this investment could be at risk. Eldridge has been designing motor cooling systems for years and we know how to do it right. Whether it is a new system design or retrofit of an existing system, let us know what we can do to make this investment a good one.