Choosing industrial fans hinges on their ability to move a specific air volume against the ventilation system’s total static pressure. But how much static pressure should we add for the fan itself? Let’s explore the three types of pressure losses caused by fans – friction, dynamic, and component – and which ones to include in the total static pressure.

Friction Pressure Loss

Friction pressure losses happen when air particles touch stationary surfaces. While significant in long ducts, most industrial fan housings are short, so these losses are minimal. Plus, fan curves already account for friction losses, so there’s no need to add them to the system’s total static pressure.

Dynamic Pressure Loss

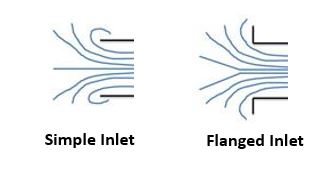

This loss occurs when airflow changes direction, spreads out, narrows, or enters and exits spaces. Industrial fans face moderate dynamic pressure loss as air enters and exits. The diagrams show air entering fans with simple and flanged openings.

These openings cause pressure loss because some air must turn 180 degrees (simple opening) or 90 degrees (flanged opening). The loss amount depends on the opening type’s loss coefficient and air velocity at the fan opening.

The good news? Most manufacturers’ fan curves already include inlet and outlet dynamic pressure losses in the fan’s performance. So, you don’t need to add these to the system’s total static pressure.

One way to lower the system’s total static pressure is by adding an inlet cone to the fan opening. The diagram shows how an inlet cone creates a smoother air entry, reducing the loss coefficient and dynamic pressure loss. If the cone maker doesn’t provide data to calculate the static pressure decrease, you can estimate it using the difference in loss coefficients between the inlet cone shape and the opening type assumed by the fan curve.

An inlet cone is useful when the total system pressure requires more fan horsepower. Adding a cone might be cheaper than the extra costs of a higher horsepower motor.

Component Pressure Loss

This loss comes from adding items like filters, dampers, hoods, and guards to a fan. You must add these pressure losses to the system’s total static pressure. Most component makers provide data to determine the pressure loss based on air velocity at each component’s inlet or outlet.

Conclusion

Adding a fan to a ventilation system doesn’t change the system’s total static pressure because the fan curve already includes friction and dynamic pressure losses. You only need to add pressure losses from fan components.

If you need to upgrade your ventilation system with additional fans, our ventilation experts can help. We will assist you with selecting the right fan for your application.