Ventilation systems for marine vessels can be extremely complex. When they are not properly designed, vessel owners may see problems such as slamming doors from high negative pressure or excessive heat from low air flow. The most common cause of these problems is under or over estimating the static pressure of the system. In this article, I’ll explain why marine ventilation system designs are so complex and how Eldridge solves problems with existing marine ventilation systems.

System Complexity

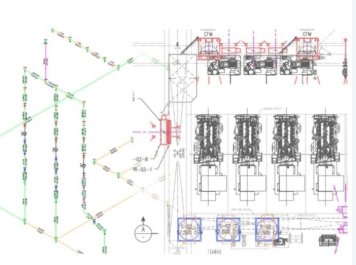

Most spaces in marine vessels are below deck and have been designed to be water tight. These confined spaces also have the danger of fires or explosions. For these reasons, marine  ventilation systems are designed to have ducted air supply and exhaust with containment dampers along with weather louvers, volume control dampers and other specified ventilation equipment/accessories. Now add in that limited space for ductwork may require combing some supply or exhaust lines for several spaces and that marine ventilation systems have both supply and exhaust fans which work together and against each other. With all this design complexity, it is not hard to see how errors in calculating static pressure can occur.

ventilation systems are designed to have ducted air supply and exhaust with containment dampers along with weather louvers, volume control dampers and other specified ventilation equipment/accessories. Now add in that limited space for ductwork may require combing some supply or exhaust lines for several spaces and that marine ventilation systems have both supply and exhaust fans which work together and against each other. With all this design complexity, it is not hard to see how errors in calculating static pressure can occur.

Problem Solving

We have seen some vessel owners try to solve ventilation problems by oversizing fans and installing additional volume control dampers to balance air flow in each space. Not only is this a costly solution, it could push fan motors to horsepower limits or cause fan propellers to stall if the air flow is too restricted. Both of these problems will eventually cause the ventilation systems to fail resulting in vessel down time and other safety related issues.

The only way to properly solve any marine ventilation system problem is to perform a fluid flow analysis (FFA). Eldridge uses proprietary FFA software to perform detailed calculations of the system pressure drops and air flows. What sets Eldridge’s FFA software apart from others is that we can program actual fan curves into the software. That allows us to specify properly selected fans to solve existing ventilation system problems.

Eldridge can provide solutions if your marine vessel suffers from an improperly designed ventilation system or if you are planning to move a cold weather rig with an undersized ventilation system to a hotter climate. Now is the right time get the correct amount of air moving through those confined spaces before summer months are here!