A successful environment is where workers are healthy, comfortable and productive. To accomplish this goal, an industrial ventilation system must make the inside temperature the same as the outside temperature. With the right number of air changes, the ventilation system will remove the solar and internal heat loads that create dangerous working conditions. If after removing these heat loads, what else can be done if the inside temperature is still very hot? The solution is to add spot cooling equipment that can provide additional heat relief. In this article, I will discuss three spot cooling solutions for an industrial ventilation system that we recommend to our customers.

HVLS Fans

High volume, low speed (HVLS) fans are a great way to add spot cooling on a large scale. HVLS fans don’t change the air temperature so their benefit is only felt when people are in the air stream. What they do is induce an evaporative cooling effect that will have a perceived temperature reduction of 8 to 10 degrees F. These fans come in a wide variety of sizes ranging from 8 to 24 ft in diameter. To provide the precise air speed for the evaporative cooling effect, HVLS fans can be equipped with speed controls. Use HVLS fans in areas where there are high concentrations of people.

Spot Cooling Fans

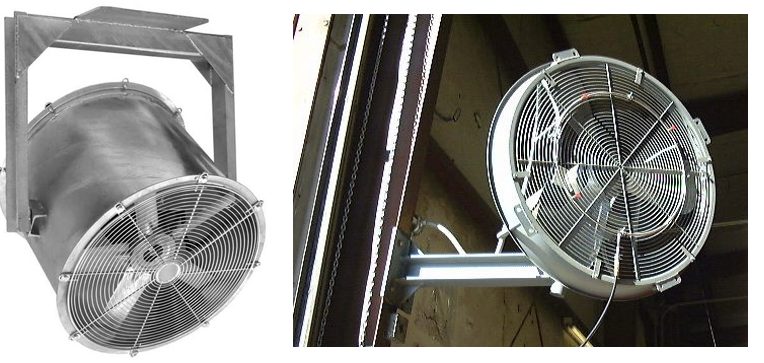

For a person working in front a machine all day, a spot cooling fan is a good way to provide heat relief. These fans are also work by inducing an evaporative cooling effect. Whether portable or stationary, spot cooling fans work best when they are located close enough to a person to provide air velocity over 200 ft/min. Spread and Throw calculations will help determine the best location for a spot cooling fan. The two images below are examples of beam mounted spot cooling fans.

Portable Evaporative Coolers

Portable Evaporative Coolers

A portable evaporative cooler (PEC) is the best way to provide heat relief to a stationary worker. Also known as “swamp coolers,” PECs utilize the science of evaporation to actually lower the air temperature. The downside to PECs is that they will increase humidity because the air leaving it will be saturated with moisture. PECs should not be used in areas where equipment or products are sensitive to humidity. Another downside is they require periodic maintenance to provide maximum heat relief and to prevent mold from forming inside the equipment.

Conclusion

An investment in spot cooling equipment is not only great for improving employee morale, it will have a financial payback. The financial benefits will be realized with higher productivity, lower employee turnover and lower absenteeism. If you need help determining the best way to invest in spot cooling equipment, call an Eldridge industrial ventilation system specialist for assistance in finding the right solution for your application.