Before the 1980s, controlling fan motor speed was limited to two-speed motors, which were costly and had long production times. The advent of variable frequency drives (VFDs) revolutionized this, offering cost-effective and nearly infinite speed control options. This article will address common questions about using VFDs for fan motor speed control and will explain the benefits and drawbacks of using VFDs.

Understanding Motor Synchronous Speed

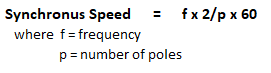

To grasp VFD operation, we must first comprehend motor synchronous speed, which depends on power supply frequency and motor winding pole count. The formula is:

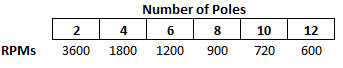

In the United States, standard 3-phase power frequency is 60 Hz (Hertz, or cycles per second). Motor winding poles always come in even numbers.

The table below shows synchronous speeds for standard US motors based on this formula:

VFD Operation Principles

VFDs function by altering the power supply frequency. Technically, a VFD first converts AC input to DC using a rectifier. Modern VFDs then employ power transistors and Pulse Width Modulation to convert DC back to AC at a different frequency.

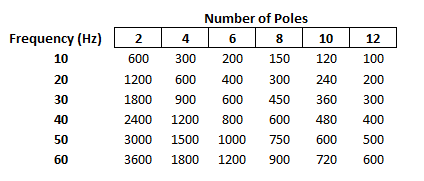

Using the synchronous speed formula, this table illustrates resulting motor speeds when a VFD changes power supply frequency:

The above table shows only a few frequency settings. VFDs can provide settings between 0% and 100% of motor speed, allowing for a wide range of synchronous speeds.

While theoretically possible to increase fan motor speed for more airflow using a VFD, two practical limitations exist. First, blade tip speed must be considered; consult manufacturer guidelines for maximum allowable speeds to prevent excess blade stress and potential failure. Second, vibration increases at higher speeds, amplifying any imbalance in the motor shaft or fan propeller, which may lead to failure. Always consult motor manufacturer guidelines before exceeding rated speeds.

VFD Benefits

Using VFDs for fan motor speed control offers several benefits:

- Airflow Regulation – VFDs allow for fan airflow reduction. For instance, in HVLS fans, increasing fan speed can enhance cooling when facility temperatures rise.

- Energy Efficiency – For variable airflow requirements, reducing fan speed lowers power consumption, resulting in energy savings. VFDs also decrease power usage during motor start-up.

- Motor Starter Elimination – VFDs eliminate the need for separate motor starters, potentially offsetting some VFD costs.

- Extended Motor Lifespan – Reduced power consumption and smoother start-ups may contribute to longer motor life.

- Motor Availability – Lower synchronous speed motors (e.g., 870 and 720 rpm) often have long manufacturing lead times. Using a VFD to control a readily available 1800 rpm motor at the required speed can be a cost-effective alternative to lengthy wait times.

- Lower Sound Level – Where fan sound level is important, VFDs allow fan speed to be reduced which also reduces fan sound to a lower level.

VFD Drawbacks

Despite their benefits, VFDs have some drawbacks:

- Compatibility Issues – Only synchronous motors with brushless AC, brushed, or permanent magnet excitation are VFD-compatible. While most new motors are compatible, it’s crucial to verify motor type when retrofitting older fan motors with VFDs.

- Mechanical Resonance Risk – A fan’s natural vibration frequency may match the power supply frequency, potentially causing significant vibrations and fan failure. This is more likely at lower frequencies. Configure the VFD to avoid these problematic frequencies.

- Reduced Motor Service Factor – VFD-controlled motors typically have a lower service factor. Consult motor manufacturers for specific limitations when using VFDs.

- Harmonic Distortion – VFD-produced frequencies may create harmonics that can damage sensitive electrical equipment. A line reactor may be necessary to mitigate this issue.

- Redundancy Considerations – While VFDs can control individual fans in multi-fan systems, it may be more cost-effective to simply turn fans on and off to regulate airflow.

Conclusion

VFDs offer significant advantages in fan motor speed control, including energy efficiency, improved airflow regulation, and potential cost savings. However, users must be aware of compatibility issues, potential mechanical resonance, and other drawbacks. By carefully considering these factors and consulting with manufacturers, facility managers can determine whether VFDs are the right choice for their specific fan motor control needs.

VFDs offer numerous opportunities to enhance the efficiency and performance of individual fans or entire ventilation systems. If you’re unsure whether VFD-controlled fan motor speed is suitable for your needs, reach out to an Eldridge ventilation specialist. We can guide you in making a wise investment to create an optimal environment in your facility.