A good ventilation system design should also consider the level of noise it adds to the existing environment. It wouldn’t be beneficial to improve the safety and comfort of a work environment by introducing fresh and cool air flow if it results in everyone needing to wear hearing protection. In this article about Ventilation System Design for a Noisy Environment, I will explore how Eldridge evaluates the effects of adding fans to a noisy environment.

Initial Ventilation System Design

It is crucial to carefully consider the size and placement of fans within a building to achieve optimal air flow without compounding any existing noise problem. Our analysis at Eldridge begins with the creation of a preliminary ventilation system design, which will determine the appropriate locations for fans to ensure optimal air flow. The design of the ventilation system is an essential factor in determining the sound levels of the fan, considering factors such as fan size, propeller type, blade pitch, and motor speed. When the initial ventilation system design is completed, we mark the location of the new fans on a diagram of the building.

Environmental Factors

After selecting fans to meet the air flow and pressure requirements for the ventilation system, the next step is to evaluate ambient noise levels by conducting a field survey. We start by marking the location of any existing equipment that produces noise on the building diagram that shows the location of the new fans. Any obstacles in the building that could potentially block or reflect sound are also marked. This information will be beneficial in case the placement of the new fans needs to be changed.

The next step is to measure the ambient sound pressure levels. When measuring the ambient sound pressure levels caused by any existing sound-producing equipment, it is recommended to do so at the nearest point to the new fan’s location where individuals may be working. For fans that are intended to be installed on the roof or high up on the walls, the closest point for measurement will be the floor directly beneath the fan, unless there is a raised walkway in closer proximity to the fans.

To accurately assess the impact of a new fan on the overall ambient sound level, it is recommended to measure the ambient sound pressure levels at each octave band rather than using a single combined reading. This requires the use of equipment capable of measuring decibel levels (dB) in the 8 octave bands that cover most of the human hearing range which is from 63Hz to 8KHz.

Combining Noise Levels

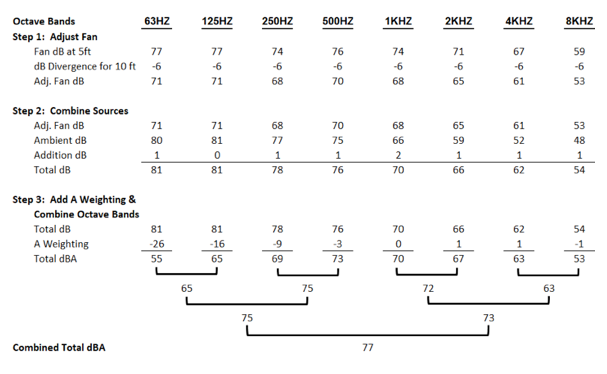

To accurately combine the sound pressure levels of a new fan and the surrounding noisy environment, an adjustment must first be made for the distance between the new fan and the point used to measure the ambient sound pressure levels. According to the 6 dB rule, for every doubling of the distance from the sound source to the measurement point, the sound levels decrease by 6 dB. For instance, if the manufacturer’s sound level measurements for the new fan were taken at a distance of 5 feet and our ambient sound measurement point is located 10 feet away from the new fan, the distance has doubled. As a result, the sound levels of the fan at each of the 8 octave bands should be reduced by 6 dB.

Two sound pressure levels are not combined in a traditional manner of averaging as they are measured on a logarithmic scale. Instead, we calculate the difference between the two sound pressure levels at each octave band and then add a factor to the highest level based on the difference. The standard method of combining two sound levels to determine the combined sound level are as follows:

- When there is a difference of 0 to 1 dB, the higher level must be increased by 3 in order to achieve the total sound level.

- If the difference is between 2 to 4 dB, the higher level should be increased by 2 to reach the total sound level.

- In the case of a difference of 5 to 9 dB, the higher level needs to be increased by 1 to match the total sound level.

- When there is a difference of 10 or more dB, there is no need to increase the higher level to reach the total sound level.

The same standard method of combining is used to combine the eight octave bands into a total sound level. We start be combing the 63 and 125Hz, the 250 and 500 Hz, the 1 and 2 KHz and the 4 and 8 KHz sound levels. The four results from those combinations are then combined, and then the two results from those combinations are combined to yield the total sound level.

Illustration

Below is an illustration of how the sound pressure levels of a new fan can be combined into a noisy environment that has total sound level of 75 dBA at the measuring point:

Based on the calculation, it was determined that the new fan will increase the ambient sound level in the noisy environment by 2 dBA. If the objective was to maintain the current ambient sound level, there are some options that can be explored to decrease the impact of the new fan noise, such as:

Based on the calculation, it was determined that the new fan will increase the ambient sound level in the noisy environment by 2 dBA. If the objective was to maintain the current ambient sound level, there are some options that can be explored to decrease the impact of the new fan noise, such as:

- Either reduce the motor speed or reduce the angle of the propeller blades. This can be achieved by increasing the size of the fans to maintain the same total amount of airflow.

- Relocate the fan further away from noise sources. A calculation can be done to determine the impact using the 6 dB rule, but it is recommended to verify the ambient sound level at the new fan position.

- Use silencers to decrease fan noise.

In most cases, we have found that the simplest solution to maintain the ambient noise is to select a larger fan with a slower motor speed.

Conclusion

When it comes to improving worker comfort and efficiency, the advantages of increasing ventilation should not be sacrificed for louder noise levels. With Eldridge’s expertise in both ventilation and noise control, we can offer a ventilation system solution that meets all of the requirements to create a successful environment in your facility.