Understanding Indirect Evaporative Cooling

At Eldridge Industrial Ventilation & Noise Control Systems, we’ve encountered various systems designed to enhance the comfort and efficiency of industrial environments. Among these, Indirect Evaporative Cooling is a standout for its unique approach to temperature management. This method leverages the natural process of evaporation to cool air indirectly, making it a compelling choice for areas where introducing additional humidity is not desirable.

The process begins with hot external air passing through a heat exchanger, where it loses heat to the evaporating water on the other side, without gaining moisture. This cooled air is then distributed throughout the building, offering a refreshing breeze without increasing the indoor humidity levels. It’s a clever system that sidesteps the issues commonly associated with traditional cooling methods.

Benefits of Indirect Evaporative Cooling

In our decades of experience, the advantages of employing Indirect Evaporative Cooling within industrial settings have become increasingly clear. This system is not just about maintaining comfortable temperatures; it’s also about optimizing for efficiency and sustainability.

Enhanced Air Quality

One of the most significant benefits is the improvement in air quality. Since the system uses fresh outdoor air, it continuously circulates new air into the space, reducing the buildup of pollutants and contaminants inside the facility.

Energy Efficiency

From an operational standpoint, Indirect Evaporative Cooling systems consume less electricity compared to traditional air conditioning units. This efficiency translates to lower energy bills and a reduced carbon footprint, aligning with our commitment to sustainable solutions at Eldridge.

Comparing Direct and Indirect Cooling Methods

The distinction between direct and indirect evaporative cooling is crucial for understanding which system best suits your needs. While direct systems introduce moisture directly into the air, indirect systems cool the air without changing its humidity level. This subtle difference can have a significant impact on the environment you’re trying to condition.

Direct systems are often favored in arid climates where the added humidity can be beneficial. However, in more humid locales or in situations where sensitive equipment could be affected by moisture, Indirect Evaporative Cooling shines as the preferable alternative.

Applications of Indirect Cooling

Industrial Spaces

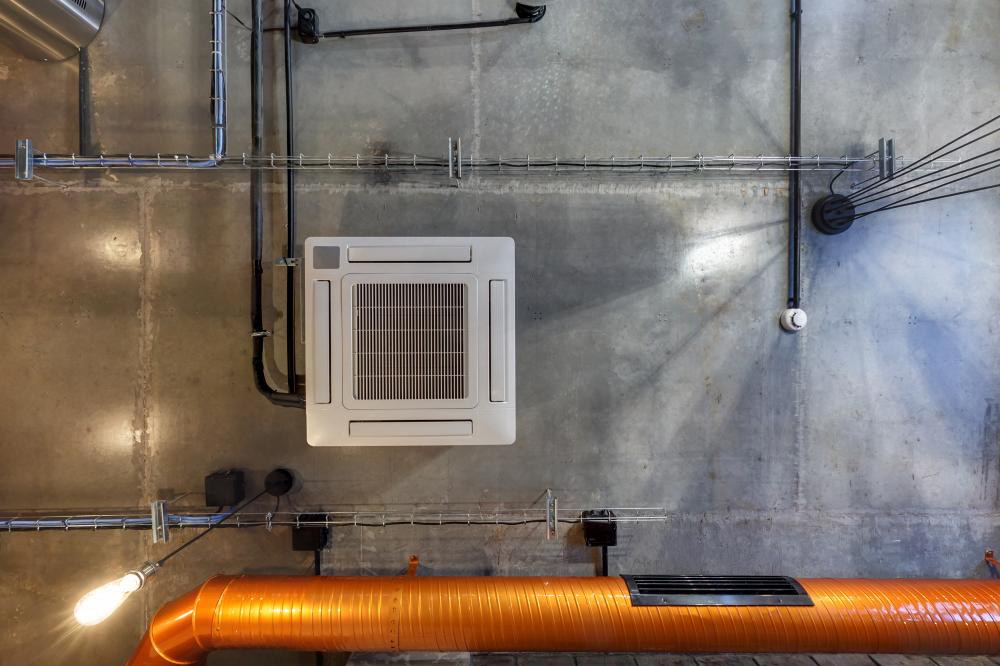

Industrial facilities, with their vast spaces and heat-generating machinery, stand to benefit greatly from Indirect Evaporative Cooling. By maintaining cooler temperatures, these systems can enhance worker productivity and protect equipment from overheating.

Data Centers

Data centers, which require strict humidity control to preserve the integrity of sensitive electronic equipment, are another prime candidate for this cooling method. Indirect systems provide the necessary temperature reduction without introducing additional moisture into the environment.

Innovative Approaches to Cooling

At Eldridge, we take pride in not just applying standard solutions but in innovatively addressing our clients’ unique challenges. Indirect Evaporative Cooling, with its inherent benefits, is just the tip of the iceberg. We delve deep into each project, considering all possible angles to devise the most efficient, cost-effective, and sustainable solutions.

Our approach is rooted in a deep understanding of thermal dynamics coupled with real-world experience. This fusion allows us to tailor our solutions, whether they involve modifying existing systems for greater efficiency or designing custom solutions from the ground up.

Case Studies and Success Stories

In one notable project, we implemented an Indirect Evaporative Cooling system for a large manufacturing facility plagued by inconsistent temperatures and high humidity levels. The results were transformative, leading to improved worker comfort, enhanced product integrity, and lowered operational costs.

This success story exemplifies our commitment to pushing the boundaries of what’s possible in industrial ventilation and cooling. It’s not just about installing equipment; it’s about crafting environments that foster health, safety, and productivity.

Choosing the Right Cooling System

Deciding on the best cooling system for your operation can be daunting. It’s not a one-size-fits-all situation. Factors like your geographic location, the nature of your operation, and specific environmental needs all play crucial roles in this decision.

That’s where experts like us come in. At Eldridge, we begin with a comprehensive assessment of your site. This initial survey allows us to understand your unique challenges and objectives. From there, we can recommend whether Indirect Evaporative Cooling or another of our innovative solutions best meets your needs.

Indirect Evaporative Cooling represents a paradigm shift in how we approach temperature regulation in industrial environments. Its ability to provide cooling efficiently and sustainably makes it an invaluable tool in our arsenal. If you’re exploring cooling options for your facility, let’s start a conversation. Together, we can determine the most effective, efficient, and environmentally friendly solutions for your needs.

What is an indirect evaporative cooler?

Imagine a cooling system that harnesses the power of natural evaporation without adding any moisture to the air you breathe. That’s the essence of an indirect evaporative cooler. At Eldridge, we’ve seen firsthand how these systems leverage a secondary air stream that never directly contacts the cooled indoor air. It’s a bit like having a cooling assistant that works tirelessly outside, ensuring the air inside stays fresh and comfortably cool without the humidity often associated with cooling. The beauty of this system lies in its simplicity and the elegance of using a fundamental process of nature to achieve significant cooling.

What are the disadvantages of indirect evaporative cooling?

While indirect evaporative cooling offers numerous advantages, it’s only fair to discuss some challenges. Primarily, these systems are most effective in dry, arid climates and might not be the best fit for areas with high humidity levels. Also, despite being more energy-efficient than traditional air conditioning, they can sometimes struggle to achieve the same degree of cooling on the hottest days. At Eldridge, we’ve encountered situations where a combination of techniques was necessary to meet the cooling demands of particularly challenging environments. It’s about finding the right balance and understanding that no single solution fits every situation.

Is evaporative cooling as good as air conditioning?

Comparing evaporative cooling to traditional air conditioning is like comparing apples to oranges; each has its strengths suited to different scenarios. Evaporative cooling shines in its energy efficiency and its ability to provide fresh, filtered air continuously. On the other hand, air conditioning can achieve lower temperatures and is more effective in humid climates. At Eldridge, we often remind our clients that the choice isn’t about which is better universally, but which is better for their specific needs, considering factors like climate, the nature of the space, and sustainability goals.

Can indirect evaporative coolers be used in humid climates?

This is a common question, and the answer is nuanced. Indirect evaporative coolers are engineered to avoid adding humidity to the processed air, making them more versatile than their direct counterparts. While they are indeed more suited to dry climates, advancements in technology have made them increasingly viable options in areas with higher humidity. However, their efficiency may be reduced under such conditions. At Eldridge, we’ve successfully implemented hybrid systems that combine indirect evaporative cooling with other cooling methods to enhance comfort and efficiency, even in more humid environments.

What innovative approaches to cooling does Eldridge explore?

At Eldridge, innovation is at the core of what we do. We’re not just about installing off-the-shelf solutions; we’re about crafting systems that meet the unique challenges of each space. Whether it’s integrating indirect evaporative cooling with renewable energy sources, or devising entirely custom solutions that rethink the way we approach temperature regulation, our focus is on efficiency, sustainability, and the specific needs of our clients. We’ve pioneered solutions that seemed unconventional at the outset but resulted in significant advances in cooling technology, demonstrating our commitment to leading edge in industrial ventilation and noise control systems.

How does Eldridge help clients choose the right cooling system?

Choosing the right cooling system can seem daunting, but that’s where our expertise comes in. Our process begins with a comprehensive assessment of your site and a deep dive into your unique challenges, preferences, and goals. This isn’t just about technical specifications; it’s about understanding your operation on a granular level. From there, we leverage our 75 years of experience to recommend solutions that align with your needs, whether that means an indirect evaporative cooler, a hybrid system, or an entirely custom approach. Our goal is to create environments that are not just cool but are optimized for health, safety, and productivity.

Cooling Resources

- U.S. Environmental Protection Agency (EPA) – The EPA’s website provides information on indoor air quality, energy efficiency, and sustainable cooling solutions.

- U.S. Department of Energy (DOE) – The DOE offers resources on energy-efficient cooling systems and technologies for industrial applications.

- ASHRAE – The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) sets standards for indoor air quality and energy efficiency in cooling systems.

- Occupational Safety and Health Administration (OSHA) – OSHA provides guidelines for maintaining safe and healthy indoor environments in industrial settings, including temperature regulation.