Eldridge’s turbine expertise includes the design and manufacturing of containment damper sets used in turbine enclosures. Our manufacturing partner, Flamgard Engineering recently completed building a set of three turbine enclosure dampers to be installed by our customer as part of a new GE LM6000 turbine and generator set. These good looking stainless steel containment dampers will be a critical part of the fire suppression system that is designed to keep men and machinery safe in the event of a fire disaster.

Turbine and Generator Room Enclosures

When installing a turbine and generator set, each of the two units are housed in separate room enclosures. The purpose of these room enclosure is to facilitate equipment cooling, sound abatement and most importantly, fire suppression. One of the most common hazards of a turbine and generator set is leaking lube oil. Should the leaking lube oil come in contact with a hot surface, a fire may ignite creating a highly dangerous and potentially deadly disaster.

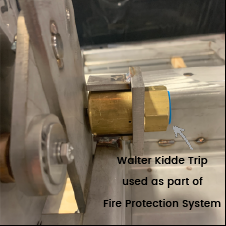

Both enclosures are equipped with a fire detection system that releases a suppressant to put out a fire. For gas turbine applications, inert gases are used to deprive the fire of oxygen and put it out. Eldridge Containment Dampers are located in the supply and exhaust vents of the two enclosures. When tripped by the fire suppression system located in either enclosure, the containment dampers close to seal the enclosure and contain the inert gas long enough to put out the fire.

Both enclosures are equipped with a fire detection system that releases a suppressant to put out a fire. For gas turbine applications, inert gases are used to deprive the fire of oxygen and put it out. Eldridge Containment Dampers are located in the supply and exhaust vents of the two enclosures. When tripped by the fire suppression system located in either enclosure, the containment dampers close to seal the enclosure and contain the inert gas long enough to put out the fire.

Conclusion

Keeping people and property safe in the event of a disaster should be a top priority for gas turbine owners. We at Eldridge are proud to apply our knowledge and extensive background to the design and manufacturing of high quality turbine enclosure dampers. We get an added bonus by helping our customers attain this safety goal.