CASPR Group has named Eldridge as their new Food Processing Industry distributor in Texas. We are excited to now offer a line of products that are more effective at combating pathogens than UV lights and HEPA filters. At a time when there is so much focus on how to use HVAC systems to keep people safe from COVID-19, we think that the CASPR products are a great solution.

How it Works

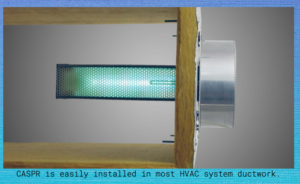

CASPR, which stands for Continuous Air and Surface Pathogen Reduction, uses UV light and a catalyst to generate negatively charge ions such as hydrogen peroxide. These molecules exit your duct, circulate the room through the air and land on all surfaces. During this process, these negatively-charged molecules are actively seeking out positively-charged molecules, like mold, bacteria, and viruses, to neutralize by killing at the molecular level. CASPR is 99.96% effective against killing these pathogens.

The Advantages of CASPR

The CASPR technology provides three distinct advantages over UV lights and HEPA filters. The first advantage is that CASPR is an active agent against airborne pathogens where the other two are passive. Envision that you are in a room with someone that coughs or sneezes. Although you may be at a safe social distance, there is a small portion of the discharge that will become aerosolized and may remain in the air for a long time. In order for UV lights and HEPA filters to remove any pathogens in the aerosolized discharge, the HVAC system must be running to move the air to the devices. Depending on the air change rate, this could take several minutes. However, the negatively-charged molecules generated by the CASPR device go to work immediately clearing the air of an aerosolized pathogens. That will significantly reduce the chance of you breathing in any of the aerosolized pathogens.

For the second advantage of CASPR, we will use the same example. The heavier drops of a cough or sneeze will settle out of the air and land on surfaces such as tables, desks, chairs, door handles and the floor. UV lights and HEPA filters do nothing to kill pathogens on these surfaces. On the other hand, the negatively-charged molecules generated by the CASPR device also land on these surfaces. Therefore, CASPR is just as effective at killing pathogens on all surfaces in a room as it is at killing them in the air.

The third advantage is that CASPR provides the 99.96% pathogen reduction killing effectiveness in the air and on surfaces for a lower cost compared to UV lights and HEPA filters. CASPR equipment is less expensive, easier and cheaper to install and the operating and maintenance costs are lower than these other devices. Overall, CASPR provides a better solution for keeping people safe at a lower cost.

Ideal Solution for the Food Processing Industry

Food processing companies already work hard to keep their products and employees protected from pathogens such as listeria and salmonella. The added burden of preventing COVID-19 transmission through air and surface contamination makes CASPR a great solution for disinfecting food preparation areas, locker rooms and break rooms. It is a simple and inexpensive way to add another layer of defense against product and people contamination.

There are no safety concerns with using CASPR in a food processing environment because the amount of hydrogen peroxide generated in the air is significantly below OSHA exposure limits. Also, hydrogen peroxide is an FDA approved food additive and is commonly used in toothpaste and milk.

Conclusion

At Eldridge, our mission is to create successful environments where people and equipment can work and operate safely and efficiently. The CASPR product gives us another way to help our customers accomplish that goal.