In Part 2: Reading a Psychrometric Chart, I demonstrated how to read a psychrometric chart by using any two air conditions to find other parameters. In the third and final part of this Pschryo Series, we will be applying psychrometrics to solve a common problem with cold storage facilities.

Humidity and Cold Storage Don’t Mix

A common problem with cold storage facilities is that too much moisture in the air can cause condensation and ice to build-up. These two conditions may create a safety hazard, reduce productivity or damage product. The best way to solve a moisture problem in a cold stage facility is to install a desiccant dehumidifier. Sizing the unit requires determining moisture that comes from people, product and penetrations. For our example problem, we are going to focus on determining the moisture that comes from penetrations such as man or forklift doors.

Our example cold storage facility is a freezer unit located in Houston, Texas. To control moisture infiltrations from the man and forklift doors, the unit will be designed to have a positive pressure. The outdoor make-up air required for a positive pressure is 1,500 CFM. The ASHRAE 1% temperature design conditions for Houston are 95°F Dry Bulb and 76°F Wet Bulb. The freezer unit will need to maintain the moisture level in the air below 25°F Dew Point to prevent ice from forming. Our problem is to determine the amount of moisture that needs to be taken out of the make-up air going into the freezer unit.

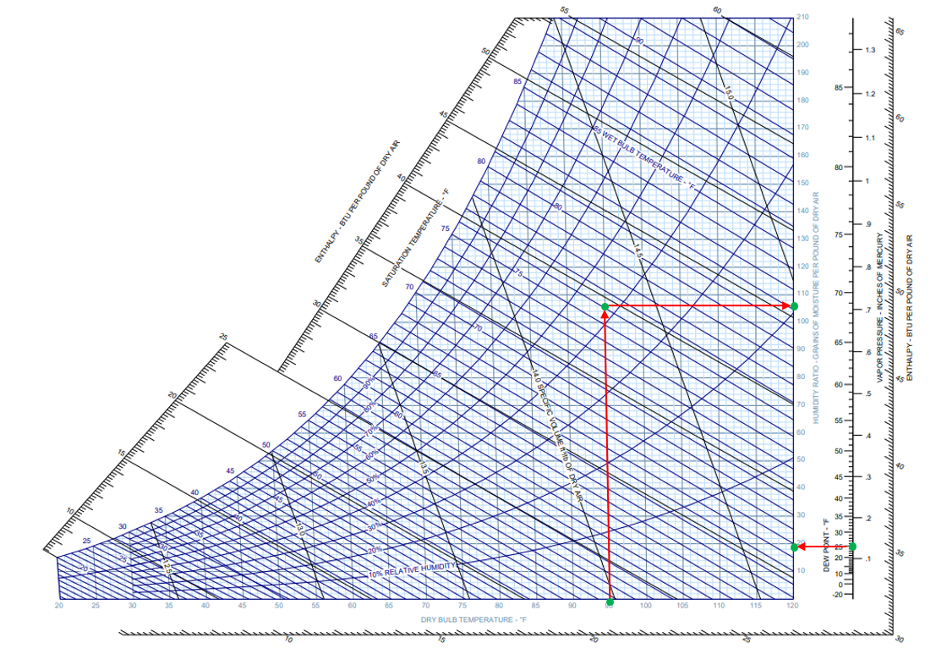

We will need to find the moisture levels in the air entering and leaving the desiccant dehumidifier. The entering air will be at 95°F Dry Bulb and 76°F Wet Bulb. We will find that point by locating the 95° Dry Bulb temperature at the bottom of the chart and going up that line until it intersects with the 76°F Wet Bulb line that is slanting down from left to right. To find the moisture in the entering air, we will draw a horizontal line to the right until it intersects with the Humidity Ratio axis which is at 106 grains per pound of dry air.

The air leaving the desiccant dehumidifier is at a 25°F Dew Point. The easiest way to find that point is to look at the Dew Point axis on the right and find 25°F. To find the moisture in the leaving air, we will draw a horizontal line to the left until it intersects with the Humidity Ratio axis which is at 19 grains per pound of dry air.

What we have determined is that the desiccant dehumidifier will need to take out 87 (106-19) grains of moisture per pound of dry air from the 1,500 CFM of make-up air. To calculate the total moisture load of the make-up air, we will need to get the Specific Volume of the entering air from the chart which is 14.3 cubic feet per pound. The result is 9,000 grains per minute or 9.25 gallons per hour.

Conclusion

What we just did was a good example of applying psychrometrics to solve an HVAC problem. Sizing software for most HVAC equipment has replaced using a psychrometric chart for many applications but, the skill of knowing how to read a psychrometric chart helps with understanding the science of psychrometrics.

The ventilation experts at Eldridge have been applying psychrometrics for a long time to help customers solve their cold storage humidity issues. Contact Eldridge today if you need help with your facility.